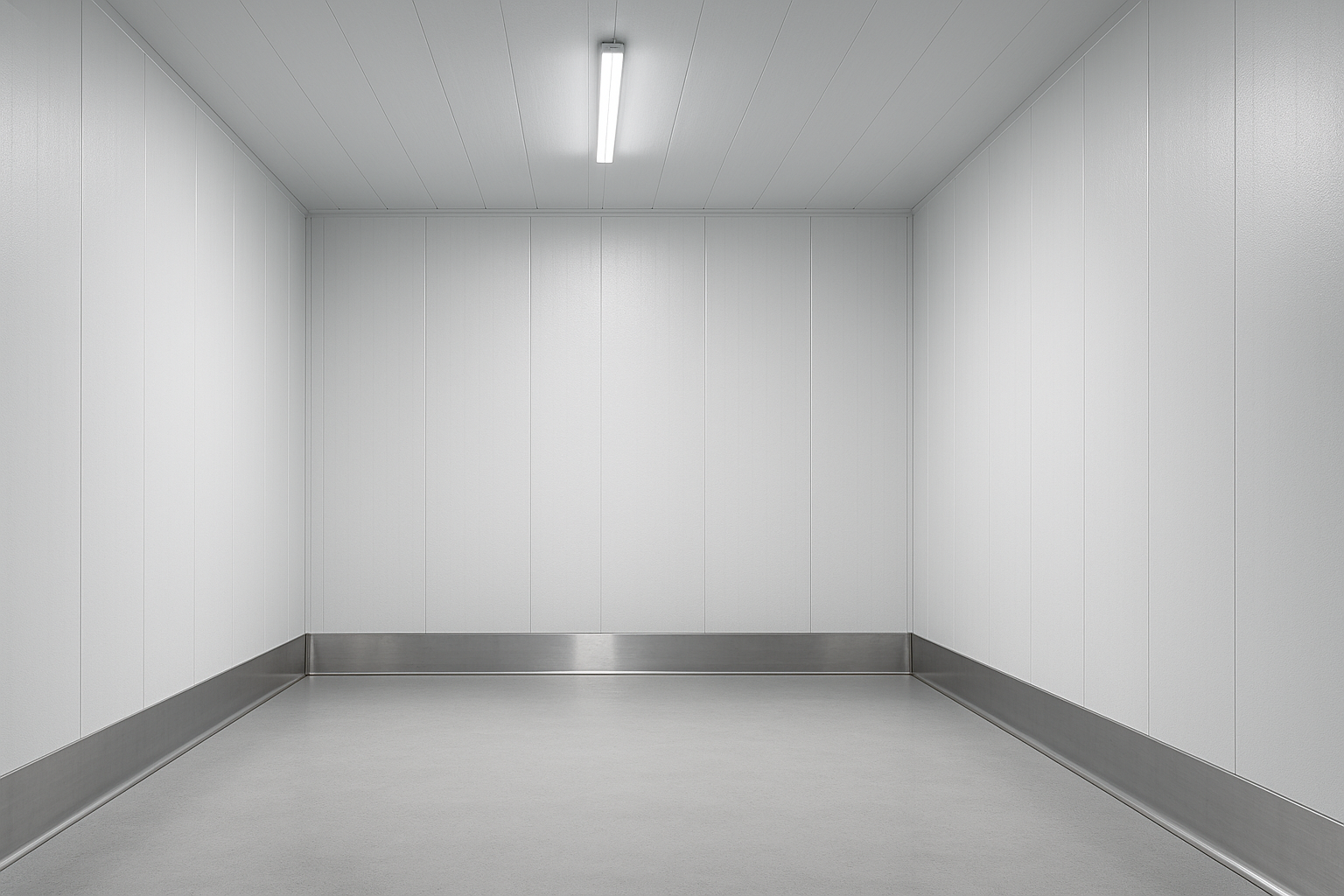

How to Join Coolroom Panels: Step-by-Step Guide for Airtight Results

A coolroom is only as good as its joints. Even premium panels can fail if the joints aren’t aligned, sealed, and fixed correctly. Use this guide to build a tighter envelope, reduce condensation risk, and keep your coolroom efficient long-term.

On this page

- 1) Choose the right panel thickness

- 2) Understand joint systems (Z-lock, cam-lock, tongue & groove)

- 3) Prep edges and site

- 4) Align and dry-fit

- 5) Seal the joint (airtight + vapour control)

- 6) Fixing & fasteners

- 7) Condensation checklist

- 8) Common mistakes

- FAQ

Related reading: How to cut cold room panels

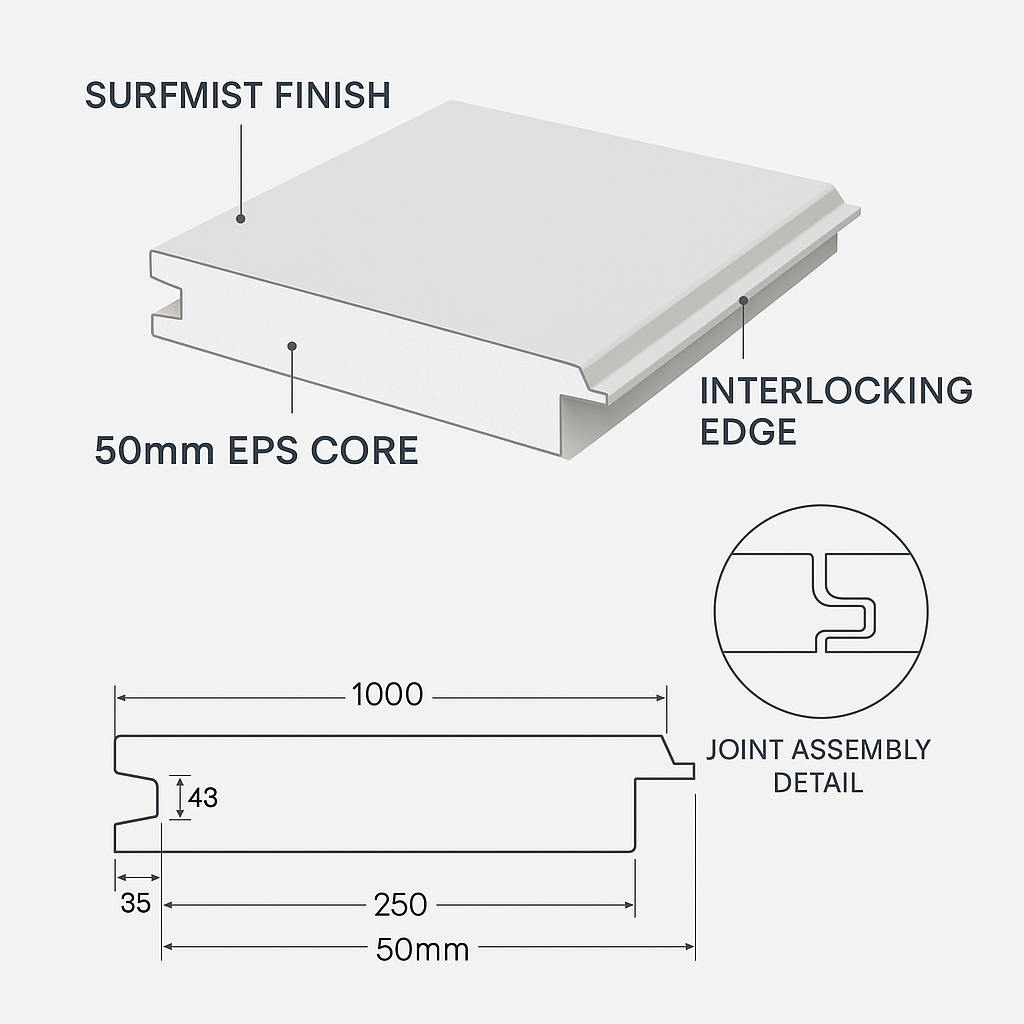

1) Choose the Right Panel Thickness (Before You Start Joining)

Panel thickness affects insulation performance, joint strength, and how stable the room stays at temperature. If you select the wrong thickness, you may fight condensation and higher running costs later.

| Thickness | Typical Use | Notes |

|---|---|---|

| 25mm | Light-duty / display use | Not ideal for serious cold storage |

| 35mm | Medium coolrooms | Works for higher coolroom temps and smaller rooms |

| 50mm | Most commercial coolrooms | Common “all-rounder” thickness |

| 75–100mm | Freezers / colder storage | Better for low temps and high ΔT environments |

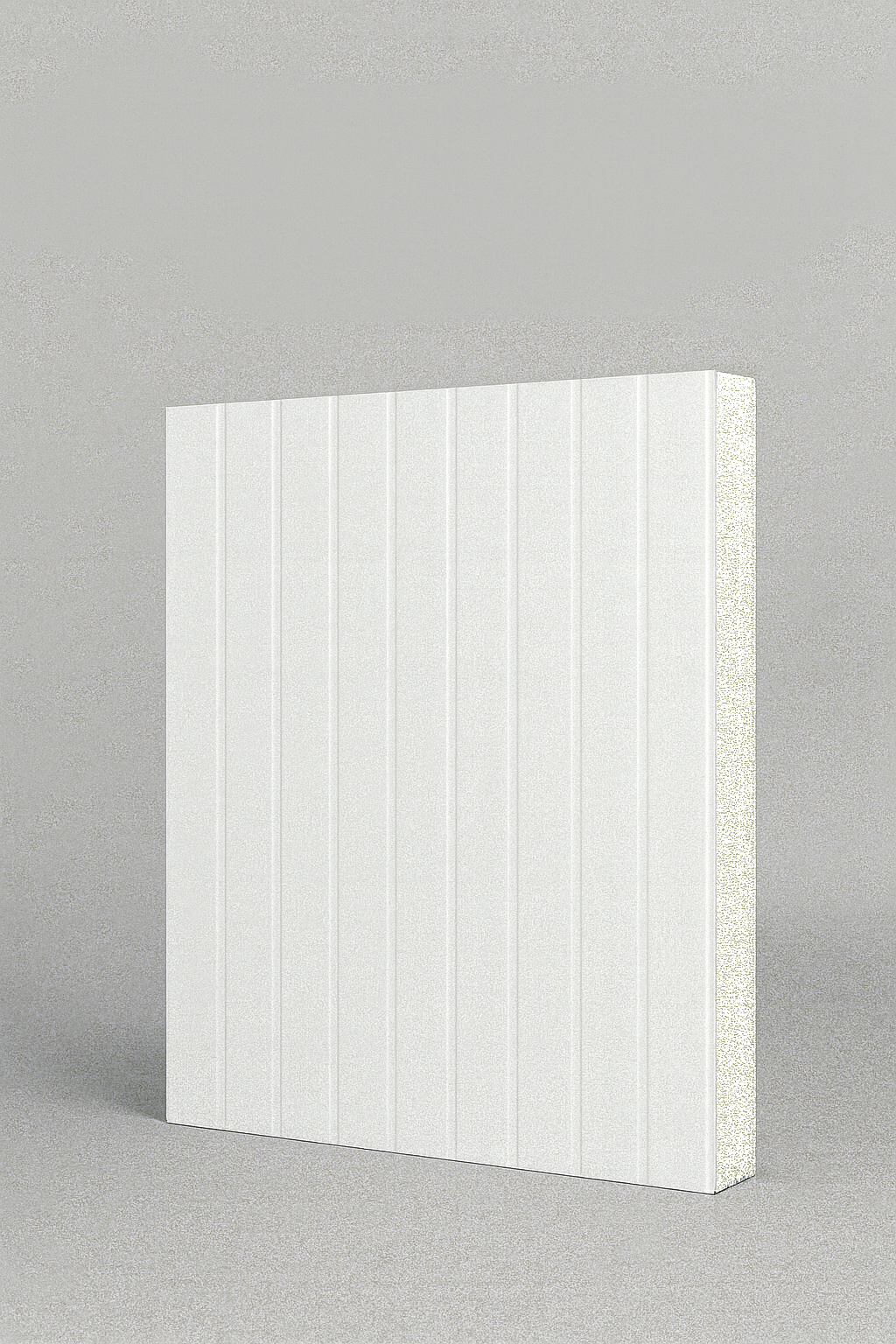

2) Understand Your Joint System

Coolroom panels don’t all connect the same way. Your joining workflow depends on the edge profile and locking method. The goal is always the same: full engagement + continuous seal.

| Joint Type | Where it’s used | What to watch |

|---|---|---|

| Tongue & Groove | Walls / ceilings | Seal the full length; avoid crushed foam |

| Cam-lock | Modular panel rooms | Perfect alignment before locking; don’t force |

| Z-lock | Sandwich panels | Panels must be square; engage fully to avoid leaks |

- a structural connection

- an airtight seal

- a vapour barrier continuation

3) Prep the Site and Panel Edges

Most joining issues start before any panel is lifted: uneven floors, dirty edges, and damaged profiles. Take 10 minutes here and you save hours later.

Site checks

- Floor/slab is level and clean

- Clear space for handling and staging panels

- Confirm your wall lines and corner reference points

Panel edge checks

- Inspect for dents, burrs, or crushed foam at the joint

- Wipe off dust/oil so sealants bond properly

- Keep cut edges protected (see cutting guide if needed)

4) Align Panels and Dry-Fit First

If the first panel is out of plumb, every panel after it becomes harder to lock and seal. Start slow.

Alignment workflow

- Set the first corner panel perfectly plumb and square.

- Dry-fit the next panel to confirm the profile engages smoothly.

- Check line and level before applying any sealant.

- Engage the joint fully (no “almost locked” seams).

- Clamp if needed so the panels don’t drift while fixing.

Tip: If you’re getting resistance, don’t force it—check for a twisted panel, debris, or a slightly out-of-square corner.

5) Seal the Joint: Airtight + Vapour Control

Sealing is where performance is won or lost. The best panels still fail if air and moisture can travel through joints. Use the right sealing method for the joint type and location.

| Seal Method | Best use | Why it works |

|---|---|---|

| PU Foam | Internal joints | Expands to fill small gaps |

| Butyl Tape | Metal overlaps / vapour barrier | Excellent long-term vapour seal |

| Silicone | External finishing only | Flexible finish (not ideal as primary internal seal) |

6) Fixing Panels: Fasteners and Spacing

Fixings keep the joint compressed and stable over time. Use the right screw type and fix into structure wherever required.

- Spacing: typically 300–400mm along joins (project dependent)

- Screws: stainless or galvanised to suit environment

- Do not overtighten: crushing foam can open leak paths

- Fix into framing/supports: don’t rely on the foam core for structural loads

If you need guidance for mounting items later, see: Can you screw into coolroom panels?

7) Condensation Checklist (Do This Before You Close It Up)

Condensation usually starts at tiny gaps in ceilings, corners, and around penetrations. Do a quick inspection after each wall and again after the ceiling.

Quick check

- All joints sealed continuously (no breaks)

- No exposed or crushed foam at edges

- Penetrations (pipes/cables) sealed immediately

- Ceiling joints and corners checked twice

- Clean out swarf/foam debris before final sealing

8) Common Mistakes (and What They Cause)

| Mistake | What happens |

|---|---|

| Skipping sealant | Air leaks → condensation → performance loss |

| Misaligned panels | Joints don’t engage fully → energy loss |

| Wrong screws / poor fixing | Loose seams and movement over time |

| Overtightening | Crushed foam → gaps and leak paths |

Want a quick estimate for your coolroom build?

Use the calculator for a ballpark, then send your size + target temperature for a proper recommendation.

Tip: Send panel thickness, room dimensions, door size, and delivery suburb/postcode for the fastest quote.

FAQ: Joining Coolroom Panels

Do I need to seal every joint, even if the panel “locks” tight?

Yes. Mechanical engagement helps, but sealing stops air and moisture movement. Coolrooms are sensitive to tiny leaks that become condensation points—especially at ceilings and corners.

What spacing should I use for screws?

Many projects use around 300–400mm spacing along joins, but it depends on the room, panel thickness, and structural requirements. Always fix into framing/supports where required.

How do I know the joint is fully engaged?

The seam should close evenly with no visible step or gap, and the panels should feel stable without spring-back. If you’re forcing it, stop and check squareness, debris, and edge damage.

What’s the best way to avoid condensation?

Continuous sealing, no exposed foam, and immediate sealing of penetrations. After installing the ceiling, re-check corners and ceiling joints because they’re the most common leak points.

Final Takeaway

Joining coolroom panels properly is a repeatable process: square setup, dry-fit alignment, continuous sealing, and correct fixing. Do those four things and you’ll get a stronger, more efficient coolroom with fewer condensation issues.

Disclaimer: This is general guidance. Always follow your panel system’s installation requirements and local building/safety rules.

My brother recommended I might like this blog.

He was totally right. This post truly made my

day. You can not imagine simply how much time I had spent

for this info! Thanks!

Thanks for the good writeup. It in fact used to be a leisure account it.

Look complex to far brought agreeable from you! By the way, how can we be in contact?