Are you wondering how strong cold room panels are for your storage needs? Choosing durable cold room panels can make all the difference in keeping your goods safe, your operations efficient, and your costs down. As a business owner, I understand the importance of investing in reliable cold storage solutions that stand up to tough conditions. In this guide, I’ll share expert insights based on real industry experience, breaking down what makes cold room panels strong, the materials behind their durability, and how to pick the best ones for your project. At Cool Room Master, we’re committed to honest pricing and real quality to deliver panels you can trust. Let’s get started!

Understanding the Strength of Cold Room Panels

When it comes to building or maintaining cold storage spaces, one question often comes up: how strong are cold room panels? The strength of these panels is crucial because they not only provide insulation but also ensure durability and safety. A cold room panel’s its ability to support loads, resist impacts, and withstand environmental conditions like moisture, temperature changes, and fire.

Cold room panels are more than just insulated walls or ceilings; they form the structural backbone of any cold storage facility. Understanding what makes a panel strong helps you choose the right materials and design for your specific needs. Whether you’re dealing with food storage, pharmaceuticals, or any temperature-sensitive products, strong panels guarantee the integrity of your cold room and protect your investment.

In this article, we’ll explore what makes cold room panels strong—from the materials used to their thickness, manufacturing standards, and real-world testing. This knowledge empowers you to make informed decisions about cold storage solutions that are both reliable and long-lasting.

What Are Cold Room Panels and Why Does Strength Matter

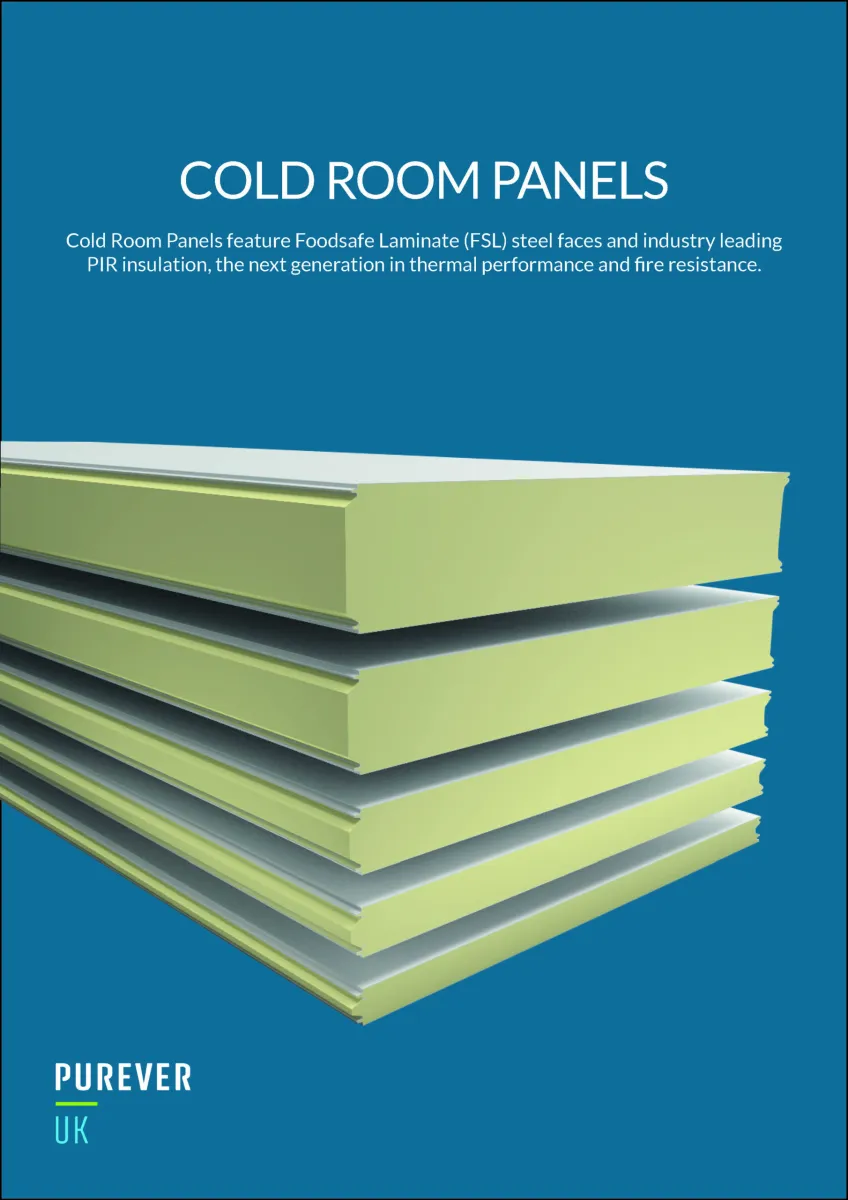

Cold room panels are insulated panels designed to build and maintain controlled temperature spaces like walk-in coolers and freezers. They usually come as sandwich panels, made with a strong outer metal layer and an insulating core, often polyurethane or similar materials. The main job is to keep temperatures steady, prevent energy loss, and protect stored goods.

Strength matters because these panels need to handle more than just cold air. They have to bear the weight of the ceiling, withstand impacts during daily use, and resist environmental factors like moisture or temperature swings. Strong cold storage panels ensure your cold room stays sealed tight, safe, and durable over time, which means less maintenance and better product protection. Whether you’re running a restaurant, grocery store, or warehouse in the U.S., picking panels with reliable cold room panel durability and load capacity is crucial for a system that stands up to real-world conditions.

Factors That Determine the Strength of Cold Room Panels Material Composition

The material makeup of cold room panels plays a huge role in their overall strength and durability. Most cold storage panels use insulating materials like polyurethane (PU) or polystyrene foam sandwiched between metal sheets, usually steel or aluminum. Polyurethane panels are popular because they offer excellent insulation and have a strong core that resists compression, making them ideal for cold room panel durability.

The metal facing not only protects the core but adds structural strength. Steel is stronger and more impact-resistant than aluminum, but aluminum panels are lighter and resist corrosion better. Some manufacturers also add coatings or laminates to improve fire resistance and environmental durability.

In short, a cold room panel with a high-quality PU core and sturdy steel facings will be stronger and last longer in harsh cold storage conditions. When you’re buying panels, always check for material specs because they tell you a lot about the panel’s load capacity and overall performance.

Factors That Determine the Strength of Cold Room Panels Panel Thickness and Density

Panel thickness and density play a big role in cold room panel strength. Thicker panels naturally offer better insulation and can handle more load, making them tougher against damage and pressure. For example, 50mm to 75mm thick panels are common options in the U.S., balancing strength and energy efficiency.

Density matters just as much. Higher-density panels mean the core material — often polyurethane (PU) foam — is packed tighter. This adds rigidity and improves the panel’s load-bearing capacity. Denser panels resist dents, impacts, and deformation better than lower-density alternatives.

Keep in mind, the right mix of thickness and density depends on your cold storage needs. A heavy-duty cold room for industrial use may require thicker, denser panels compared to a small commercial cooler. Choosing this balance ensures your cold room panels stay strong, durable, and reliable over time.

Factors That Determine the Strength of Cold Room Panels Manufacturing Standards

Manufacturing standards play a big role in how strong cold room panels are. Panels made with strict quality control and certified processes tend to be more durable and reliable. Look for panels that meet industry standards like ASTM or ISO, as these ensure consistent material quality and proper construction methods.

Good manufacturers use techniques like precise bonding of the insulation core to metal skins, and they test panels rigorously before shipping. This reduces weak spots and increases overall panel strength. Also, panels built under strong manufacturing standards better resist warping, water damage, and other issues that can happen in cold storage environments.

If you’re buying polyurethane or sandwich panels from respected manufacturers near you—whether in cities like Houston, Chicago, or Miami—you can expect panels that meet both safety and performance criteria. So, always check the manufacturing certifications and reviews to pick panels built tough enough for your cold room needs.

Factors That Determine the Strength of Cold Room Panels Environmental Resistance

Environmental resistance plays a big role in how strong cold room panels stay over time. Panels need to handle things like moisture, temperature swings, and even chemicals without breaking down. For example, in humid places or areas with lots of condensation, panels that absorb water can weaken and lose insulation power.

Materials like polyurethane foam inside insulated panels help with moisture resistance, while strong outer skins—often made of aluminum or coated steel—protect against corrosion and weather damage. UV exposure can also cause some panels to become brittle if they’re not treated properly.

When picking cold room panels, especially for a place dealing with harsh climates or constant temperature changes, look for panels rated for environmental resistance. This ensures they’ll keep their strength, insulation, and performance for years, which is crucial for maintaining cold storage conditions without costly repairs or replacements.

How Strong Are Cold Room Panels Key Metrics and Tests Load-Bearing Capacity

When it comes to cold room panel strength, load-bearing capacity is one of the most important metrics. This measures how much weight the panel can hold without bending, breaking, or losing insulation performance. In the U.S., cold storage facilities rely on panels that can safely support heavy racks, equipment, and sometimes even ceiling loads like lighting or HVAC systems.

Cold room panels made with high-quality polyurethane insulation and durable outer layers like aluminum or steel typically offer higher load capacity. Thickness matters too—panels that are 50mm or more thick usually provide better strength and support compared to thinner ones like 25mm panels.

Testing for load-bearing capacity usually involves applying pressure or weight to panels until they reach their limit. Manufacturers follow industry standards to ensure the panels can handle real-world demands—whether it’s a heavy rack of frozen goods or structural weight from the cold room ceiling.

In short, strong cold room panels with a solid load-bearing capacity help keep your cold storage setup safe and reliable, reducing risk of damage over time and protecting the stored products effectively.

How Strong Are Cold Room Panels Key Metrics and Tests Impact Resistance

Impact resistance is a crucial factor when evaluating cold room panel durability. These panels need to withstand knocks, bumps, and occasional hits during installation or daily use without cracking or losing insulation quality. Panels with high impact resistance protect your cold storage from damage caused by equipment, pallets, or accidental collisions.

Manufacturers test impact resistance by simulating real-world hits to ensure panels hold up under pressure. The better the panel’s material composition and thickness, the stronger it will resist dents and punctures. For example, polyurethane cold room panels typically offer excellent impact durability compared to other insulation types.

Strong impact resistance helps maintain the panel’s structural integrity and cold storage efficiency, reducing costly repairs and downtime. When choosing cold storage panels, consider their tested impact ratings and ask suppliers about results from drop or puncture tests to ensure you get a robust product.

For more on cold room panel materials and durability, check out Cool Room Master Panels and how they meet industry standards for strength and performance.

How Strong Are Cold Room Panels Key Metrics and Tests Fire Resistance

Fire resistance is a critical factor when evaluating cold room panel strength. In the U.S., fire safety standards demand that cold storage panels slow down the spread of flames and reduce smoke production. High-quality cold room panels, especially those with polyurethane foam cores, often meet or exceed these standards.

Here’s what makes fire-resistant cold room panels strong in this area:

- Material Composition: Panels with fire-retardant additives or non-combustible facings (like aluminum or steel) perform better.

- Testing Standards: Labs test panels for flame spread, smoke toxicity, and heat resistance under real conditions.

- Certifications: Look for panels certified by recognized agencies such as ASTM or UL for fire resistance.

Choosing fire-resistant cold storage panels isn’t just about meeting legal rules—it also protects your investment, equipment, and most importantly, the people working in or around your cold room. Keep this in mind when shopping for cold room panels to ensure safety without sacrificing panel durability or insulation efficiency.

How Strong Are Cold Room Panels Key Metrics and Tests Real-World Performance

When it comes to real-world use, cold room panels prove their strength by how well they hold up under daily wear and tear. This means standing up to heavy loads, temperature swings, moisture, and sometimes accidental knocks. In the U.S., reliability matters whether you’re running a food storage facility or a pharmaceutical cold room.

Here’s what you can expect from quality cold storage panels in real settings:

- Consistent Insulation – Panels keep temperatures steady even with frequent opening and closing, which helps protect stored goods.

- Durability Against Impact – Panels resist dents and damage from carts, forklifts, or moving equipment in busy warehouses.

- Moisture and Mold Resistance – Strong sealants and materials prevent moisture from seeping in, avoiding mold growth and breakdown over time.

- Long-Term Load Bearing – Panels maintain their structural support without sagging or warping under racks or ceiling weight.

- Fire Safety in Action – Fire-resistant panels slow down flame spread which is crucial for safety and compliance in commercial cold rooms.

Brands that meet rigorous U.S. testing standards give you confidence their panels won’t fail you on the job. Real-world strength combines all these factors to ensure your cold storage setup stays solid, safe, and efficient for years.

Comparing Cold Room Panel Strength Across Brands

When it comes to choosing cold room panels, not all brands are created equal in terms of strength and durability. Some brands focus heavily on using high-quality materials like polyurethane insulation and sturdy aluminum or steel facings, which directly boosts cold storage panel strength. Others might offer thinner panels or lower-grade materials to keep costs down, but that can impact long-term performance.

Here’s what to look out for when comparing cold room panel strength across brands:

- Material quality: Brands that use premium polyurethane or PIR insulation tend to have better load capacity and thermal properties.

- Panel thickness and density: Leading brands typically offer a range of thicknesses (like 50 mm, 75 mm) with consistent density, which improves durability and insulation.

- Manufacturing standards: Reputable manufacturers follow strict production and testing processes, ensuring panels meet fire resistance and impact standards.

- Warranty and support: Stronger panels come backed by solid warranties and customer service, reflecting confidence in product durability.

- User reviews: Local customer feedback from places like Houston, Atlanta, or Chicago can provide real insight into cold room panel durability in different climates.

Brands like Cool Room Master, Bondor, and Alpha are popular in the US market because they balance cost with proven strength and insulation. Always ask your supplier about panel testing results and certifications to confirm you’re getting panels built to handle your specific cold storage needs.

Choosing the Right Cold Room Panels for Your Needs

Picking the right cold room panels comes down to matching their strength and features with your specific requirements. Here’s what you should keep in mind:

- Material Type: Polyurethane panels are widely favored in the US for their excellent insulation and durability. They offer a good balance between strength and energy efficiency.

- Panel Thickness: Thicker panels, like 50mm or 75mm, provide better load capacity and insulation. If your cold room needs to handle heavy loads or maintain ultra-low temperatures, go thicker.

- Environmental Resistance: Consider panels that resist moisture, mold, and corrosion, especially in humid or coastal areas. This helps keep the panels strong and lasting longer.

- Fire Resistance: Look for fire-rated panels if your facility requires added safety. Fire-resistant cold room panels give you peace of mind without sacrificing strength.

- Brand and Compliance: Choose panels from reputable manufacturers who meet US standards and offer proven load-bearing capacity and impact resistance.

- Installation and Accessories: Panels that come with easy-fitting cam locks, reliable seals, and compatible doors help maintain the panel’s strength and insulation over time.

By focusing on these points, you can find durable cold storage solutions that fit your budget and keep your goods safe and properly stored.

Maintenance Tips to Ensure Long-Term Panel Strength

Keeping your cold room panels strong over time means regular maintenance is a must. Here’s how you can ensure your cold storage panel strength lasts:

- Clean Panels Regularly: Dirt and grime can wear down the surface material. Use mild soap and water to clean panels without damaging insulation.

- Check for Damage: Inspect panels for dents, cracks, or gaps. Fixing any damage quickly prevents moisture or pests from compromising the panel’s durability.

- Maintain Seals and Joints: Tight seals keep cold air in and moisture out. Look for worn-out seals or loose cam locks and replace them as needed.

- Control Humidity Levels: High humidity can cause condensation and rust on metal parts. Use proper ventilation or dehumidifiers in your cold room.

- Watch for Corrosion: In harsh environments, metal edges or fittings may corrode. Treat rust spots early to stop spreading.

- Schedule Professional Inspections: Annual check-ups by experts can catch hidden issues before they reduce your cold room panel’s strength.

- Avoid Overloading Panels: Don’t exceed recommended load-bearing capacity; excess weight may damage or warp panels over time.

Following these steps helps your cold room panels stay durable and perform well, saving you money and preventing costly repairs in the future.