By Cool Room Master | Updated October 2025 | Category: EPS Panels & Construction Innovation

Introduction: Why Expanded Polystyrene Panels Are Reshaping Australian Construction

Across Australia’s building industry, expanded polystyrene panels (EPS panels) are revolutionising the way homes and commercial spaces are designed, built, and insulated. Known for being lightweight yet strong, energy-efficient yet affordable, these panels offer an incredible balance of performance and versatility. From Adelaide’s dry heat to Melbourne’s coastal humidity, EPS panels are helping builders meet modern energy standards and aesthetic goals.

At Cool Room Master, we’ve seen a surge in demand for EPS wall panels, EPS roof panels, and expanded polystyrene sandwich panels across residential, industrial, and commercial applications. In this article, we’ll explore ten innovative ways expanded polystyrene panels are redefining Australian home design — plus key benefits, sustainability insights, and how to choose the right supplier.

Key Benefits of Using Expanded Polystyrene Panels

Lightweight and Easy to Install

EPS panels weigh a fraction of traditional brick or concrete systems, making transport and on-site handling effortless. Builders can cover large wall or roof areas quickly without cranes, reducing labour and project timelines. Their precision-cut edges ensure seamless assembly, ideal for both DIY and professional installations.

Exceptional Thermal Insulation

The closed-cell structure of expanded polystyrene traps air within its matrix, giving it an impressive thermal resistance (R-value). Homes built with EPS wall and roof systems stay cooler in summer and warmer in winter — saving energy and improving comfort throughout Australia’s diverse climates.

Cost-Effective and Energy Efficient

Compared to alternatives like concrete or aerated blocks, EPS panels offer outstanding insulation at a lower cost per square metre. They also meet NatHERS energy efficiency targets, helping homeowners and builders achieve compliance with minimal expense.

Durability and Weather Resistance

EPS materials are moisture-resistant and do not rot, warp, or degrade over time. When properly rendered or cladded, they withstand Australia’s UV exposure and unpredictable weather conditions for decades.

10 Innovative Uses for Expanded Polystyrene Panels in Home Design

From structural walls to decorative features, expanded polystyrene panels are not just for cool rooms anymore. Here are ten creative and practical ways Australian builders and homeowners are using EPS to enhance design, performance, and sustainability.

1. Structural Wall Systems

EPS wall panels form the backbone of many modern homes and commercial spaces. Acting as both insulation and structure, these panels can be rendered, cladded, or painted to achieve any aesthetic. Unlike timber or metal framing, EPS systems minimise thermal bridging, creating a continuous insulating envelope around the building.

In regions like South Australia, EPS structural walls help reduce energy bills and maintain consistent indoor temperatures. They’re ideal for residential builds, retail fit-outs, and modular extensions.

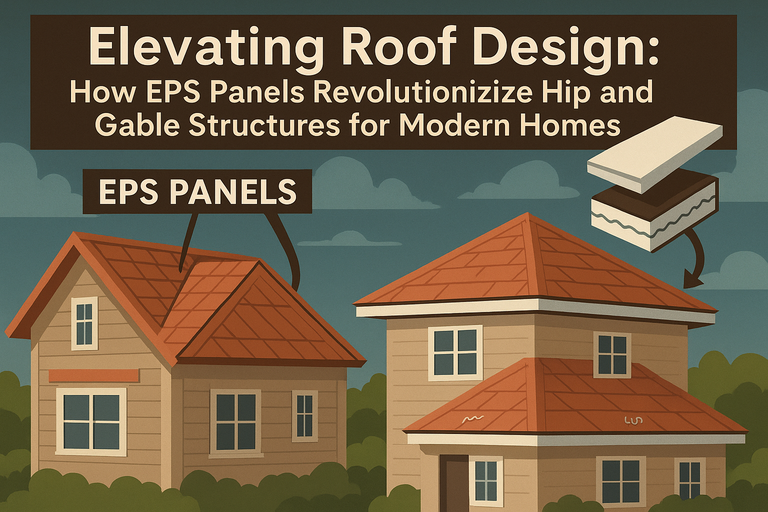

2. Roof Insulation and Lightweight Roofing

Expanded polystyrene roof panels deliver superior heat reflection and sound absorption. These panels are often used in skillion, flat, and gabled roof designs where reducing load on trusses is essential. The reflective surface and core insulation prevent radiant heat transfer, making them perfect for sheds, schools, and energy-smart homes.

3. Under-Slab and Flooring Systems

EPS boards are an excellent solution for under-slab insulation. They prevent heat loss through concrete floors, especially in cooler southern climates. Builders also use EPS as lightweight fill material for uneven sites or raised floor systems. It offers high compressive strength and moisture protection, ideal for underfloor heating applications.

4. Decorative Architectural Mouldings

Architects love EPS for its versatility. Intricate mouldings, cornices, trims, and façade details can be cut and shaped with precision. Once coated or rendered, EPS decorative elements mimic traditional plaster or stone at a fraction of the cost and weight. Many Australian design studios now rely on EPS mouldings for modern facades and interior accent walls.

5. External Cladding and Facade Systems

EPS cladding boards are a staple of energy-efficient building design. They provide a smooth, paintable surface for render or texture coatings. In modern home architecture, EPS cladding replaces heavy brick veneers, resulting in lower structural loads and faster project completion. EPS boards can also be combined with fibre-cement or composite panels for hybrid façades.

6. Energy-Efficient Retrofits

Homeowners renovating older properties use EPS sheets to improve thermal performance without extensive demolition. Installing EPS insulation behind existing walls or under roofing materials can dramatically increase energy efficiency. Lightweight EPS sheets also serve as external retrofit cladding for thermal upgrades in older brick homes.

7. Soundproofing and Acoustic Design

EPS foam has strong acoustic absorption properties. It’s increasingly used in studios, apartments, and home offices to dampen noise transmission between rooms. When combined with plasterboard or acoustic membranes, EPS panels help meet Australian NCC acoustic requirements while maintaining low build weight.

8. Prefabricated Modular Housing

The rise of modular and prefabricated housing in Australia owes much to EPS panel technology. Panels are manufactured offsite with integrated conduits for wiring and plumbing, then assembled rapidly onsite. This reduces waste, build time, and environmental impact. Companies specialising in sustainable housing use EPS modules as walls, floors, and roofs in fully transportable home systems.

9. Sustainable Landscaping and Outdoor Structures

EPS panels and blocks are being repurposed in landscaping — as cores for retaining walls, outdoor seating, garden planters, and pergola infills. They provide shape and volume without heavy excavation. Coated EPS blocks can even serve as sub-bases for decorative stone or concrete surfaces, blending function with creativity.

10. DIY and Custom Interior Furniture

Innovative homeowners and interior designers use EPS to craft lightweight furniture, display units, and exhibition pieces. Coated or laminated EPS boards can become shelving, wall art, or partition panels. The ease of cutting, painting, and coating makes EPS an ideal material for creative experimentation in modern Australian homes.

Expanded Polystyrene Sandwich Panels: Strength Meets Simplicity

EPS sandwich panels are engineered systems where a polystyrene core is bonded between two structural skins — typically pre-painted steel or aluminium. The result is a high-strength, insulated building panel ideal for cool rooms, warehouses, modular buildings, and homes.

Advantages of EPS Sandwich Panels

- High structural integrity with minimal weight

- Fast installation with interlocking joints

- Exceptional energy performance (high R-values)

- Fire-retardant options available for compliance

- Moisture-resistant and hygienic, perfect for food-grade spaces

Comparing EPS with Other Insulation Materials

Styro Sheet vs. EPS Foam

While both Styro Sheet (XPS) and EPS foam are forms of polystyrene, they differ in density and performance. EPS is produced by expanding beads of polystyrene, creating small, closed air pockets that offer excellent insulation. XPS, meanwhile, is extruded, forming a more uniform structure. For most residential projects, EPS provides better cost efficiency and environmental friendliness.

Traditional Insulation vs. Expanded Polystyrene Insulation

Compared to mineral wool or fibreglass, EPS offers a cleaner, easier-to-install alternative with no fibres or dust. It maintains consistent R-values over time and resists moisture absorption, ensuring long-term performance in Australia’s varied climates.

EPS vs. Polyurethane (PU) Panels

PU panels offer slightly higher R-values per thickness, but EPS wins in cost, recyclability, and stability under heat. For homes seeking affordability and thermal performance, EPS remains the go-to material.

Sustainability and Recycling of Expanded Polystyrene

Recycling and Reuse in Australia

EPS is 100% recyclable. Many Australian facilities — including EPSA and Foamex — collect offcuts and waste for repurposing into new insulation, packaging, or construction products. Builders can easily transport and compact EPS waste on-site, reducing landfill contributions.

Longevity and Life-Cycle Efficiency

When installed correctly, EPS panels can last 50 years or more. Their durability and low maintenance reduce the need for frequent replacements, which contributes to long-term sustainability. The embodied energy used to manufacture EPS is offset quickly through years of energy savings during building operation.

Conclusion: Choosing the Right Expanded Polystyrene Supplier in Australia

Expanded polystyrene panels are more than just insulation — they’re a cornerstone of modern Australian building design. Whether for structural walls, roof systems, or creative interiors, EPS offers versatility, efficiency, and sustainability unmatched by traditional materials.

When selecting EPS products, choose a trusted Australian supplier who understands compliance and quality standards. At Cool Room Master, we manufacture and supply expanded polystyrene wall and roof panels designed to meet the highest performance benchmarks.

Explore our complete product range, request a quote, or contact our Adelaide-based team for tailored solutions.