How to Cut Coolroom Panels Like a Pro: Step-by-Step Guide for Clean and Safe Results

Cutting coolroom panels might seem intimidating at first — especially when you’re working with EPS or PIR cores, metal skins, and various thicknesses like 50mm, 75mm, or even 100mm insulated roof panels. But with the right tools, techniques, and safety precautions, you can get professional results whether you’re building a cold room, a granny flat, or a DIY coolroom for sale.

In this guide, we’ll show you exactly how to cut coolroom panels, what tools to use, and how to maintain the integrity of the insulation and surface finish.

🧰 Tools You’ll Need to Cut Coolroom Panels

Before you begin, gather the essential tools. These tools work best for EPS sandwich panels, 50mm coolroom panels, and other standard builds.

✅ Recommended Tools:

Circular Saw or Panel Saw (with a fine-toothed blade)

Stanley Knife/Utility Knife (for trimming insulation)

Measuring Tape

Straight Edge / T-Square

Marker or Chalk Line

Protective Gear: Gloves, goggles, and dust mask

For precise cutting, a track saw can be a game-changer, especially on 75mm EPS sandwich panels or insulated roof sheeting.

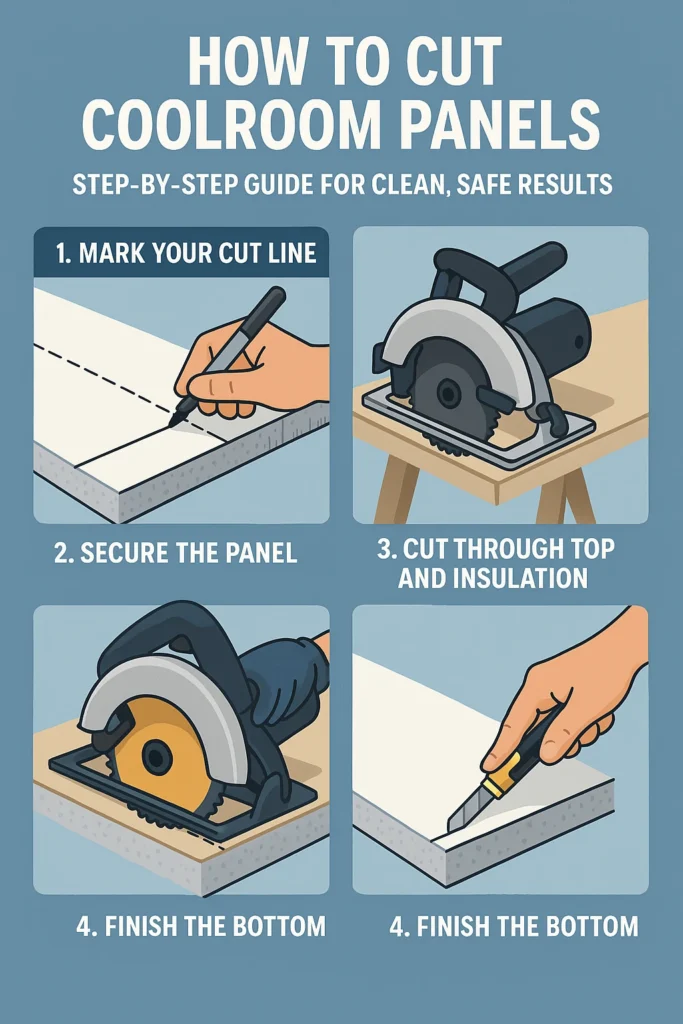

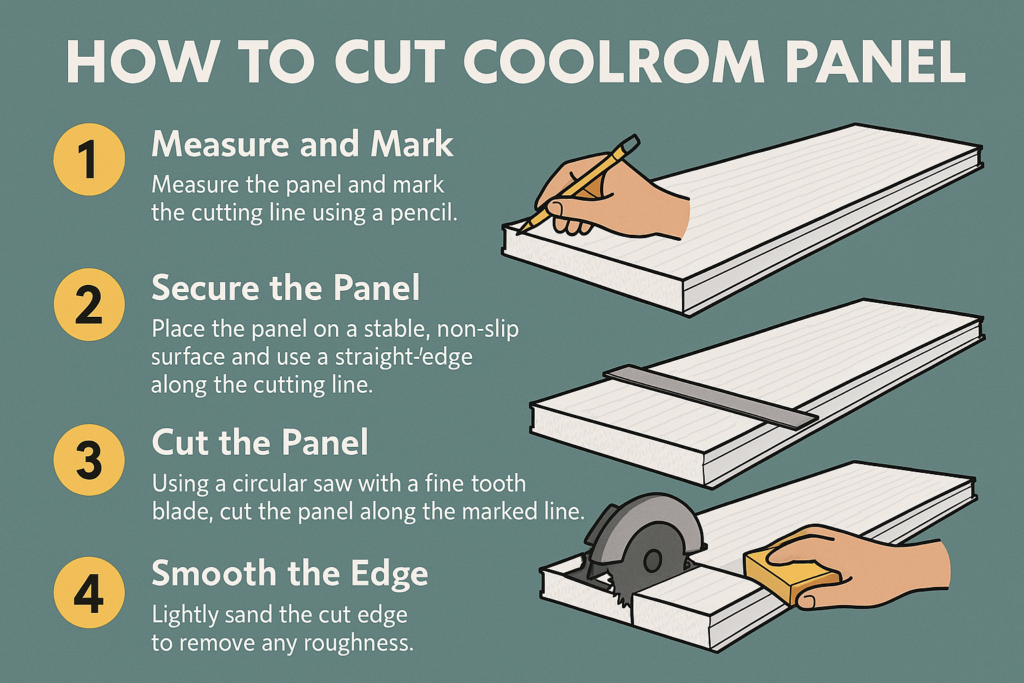

✂️ Step-by-Step: How to Cut Coolroom Panels

1. Mark Your Cut Line

Using a straight edge, chalk line, or T-square, mark your cutting line clearly. This ensures a clean, square edge—especially important when installing coolroom doors or framing with 50mm C channel.

2. Secure the Panel

Lay your panel flat on sawhorses or a stable surface. Ensure it doesn’t shift during cutting to avoid jagged edges.

3. Start with the Metal Skin

Use your circular saw to score the top metal skin of the panel. Cut slowly and steadily to avoid overheating or burring the edge.

4. Cut Through the Insulation

Once the metal is cut, use your utility knife to slice through the EPS core or polyurethane foam. This will minimize mess and allow for a cleaner internal cut.

5. Finish the Bottom Skin

Repeat the saw cut on the underside skin, following your initial cut line through the insulation.

🧼 Pro Tips for a Cleaner Cut

Cut with the decorative/visible side up to avoid chipping

For surfmist color panels, cover with painter’s tape to prevent scratches

Use a vacuum or blower to remove EPS dust post-cutting

Use adhesive flexible sealant after installation for a tight seal

Working with cool room panels perth or cold room panels for sale? These panels often feature aluminium extrusions or channel joiners — always pre-measure for framing accuracy.

🔐 Safety First: Cutting Panels Without Risk

Always wear eye protection — cutting metal skins can produce flying shards

Use ear protection with power saws

Avoid cutting near flammable materials

If using surfmist spray paint to touch up cut edges, only do so in ventilated areas

🏗️ Where Are Cut Coolroom Panels Used?

Accurately cut panels are essential for:

Flat pack granny flats

Do-it-yourself granny flat builds

Refrigerator room installations

Coolroom shelving and wall panelling

Whether you’re assembling a coolroom panel kit, installing insulated wall panels Australia-wide, or working on a granny flat pack, accurate cutting is key to long-lasting, energy-efficient results.

💬 Frequently Asked Questions

❓ Can I cut 50mm panels with a hand saw?

Yes, but it’s not recommended for long or repeated cuts. A circular saw provides faster, cleaner results.

❓ What’s the best way to cut a panel for a coolroom door frame?

Use a jigsaw or plunge saw to create an opening, then seal the edges with adhesive flexible and aluminium channel for strength.

❓ Can I re-use offcuts?

Absolutely. Use smaller offcuts for fridge panel backing, freezer panels, or even insulation for sheds.

🛠️ Need Help? Cool Room Master Has You Covered

We supply:

Coolroom panels for sale in 50mm, 75mm, and 100mm sizes

Cold room doors, accessories, and surfmist color finishes

Granny flat kits, DIY coolroom kits, and more

I do like polystyrene for its insulating properties but Please can you tell me if the polystyrene has any fire retardant treatment. As i have put a flame to polystyrene before and it burns like a firestarter cube.

I’ve been browsing online more than three hours today, yet I never found any interesting article like

yours. It’s pretty worth enough for me. Personally, if all site owners and bloggers made good

content as you did, the web will be a lot more useful than ever before.

It’s actually a nice and useful piece of info. I am glad that you

simply shared this useful information with us.

Please keep us informed like this. Thank you

for sharing.