How to Cut Insulated Panels Safely (Tools, Steps & Edge Sealing)

Cutting insulated panels looks simple—until you chip the coating, crush the foam core, or leave an edge that leaks air and moisture. This guide shows a clean, repeatable method to cut panels for cool rooms, sheds, workshops, and insulated wall/roof builds, plus the tool choices that prevent expensive rework.

On this page

- Know your panel type first

- Best tools (and blades) for clean cuts

- Worksite setup & safety

- Step-by-step cutting method

- How to protect & seal cut edges

- Common mistakes to avoid

- FAQ

Related guides: How to cut cold room panels • How to join coolroom panels

1) Know Your Panel Type First (Because the Cutting Method Changes)

“Insulated panel” can mean a few different products. The core (EPS/PU/PIR) is usually easy to cut, but the skin (steel, aluminium, OSB, or composite) is where most damage happens. Identify what you’re cutting before you choose a blade.

| Panel Type | Typical Skin | Best Cutting Approach |

|---|---|---|

| Foam-core panels (EPS / PU / PIR) | May be plain foam or faced | Fine-tooth saw for straight cuts, knife for trimming; keep the foam supported to avoid tearing. |

| Insulated metal panels (IMP) | Steel / coated metal | Use metal/composite-safe blades or shears; avoid overheating and always protect cut edges. |

| Structural insulated panels (SIPs) | OSB / board skins | Circular/track saw with the right blade; plan penetrations early to avoid site rework. |

2) Best Tools (and Blades) for Clean, Accurate Cuts

Clean cuts come from the right blade, a straight guide, and a panel that doesn’t move. Here are the most practical tool choices for insulated panel work.

- Circular saw (straight cuts) + correct blade for your panel skin

- Straightedge / track (keeps cuts perfectly straight)

- Clamps (stops vibration and chipping)

- Utility/insulation knife (scoring and trimming foam)

- Vacuum/dust extraction (foam dust and metal swarf)

Tools to avoid (they cause most of the damage)

- Abrasive cut-off wheels (heat + sparks can damage coatings and seals)

- Grinding through long cuts (rough edges, coating burn, corrosion risk)

- Any “rush cut” without support (crushed foam, crooked joints, gaps)

3) Worksite Setup & Safety (Don’t Skip This)

Most cutting accidents (and ugly cuts) happen because the panel shifts or the work area is cluttered. Set up properly and you’ll cut faster and cleaner.

- Safety glasses

- Cut-resistant gloves (metal skins can be razor sharp)

- Dust mask/respirator (foam dust is fine and irritating)

- Hearing protection for power tools

- Long sleeves/pants

- Use a flat, stable surface (saw horses + sacrificial boards work well).

- Support both sides of the cut to prevent the panel “pinching” the blade.

- Mark lines clearly and keep a straight guide clamped in place.

- Cut in a well-ventilated area and vacuum dust/swarf as you go.

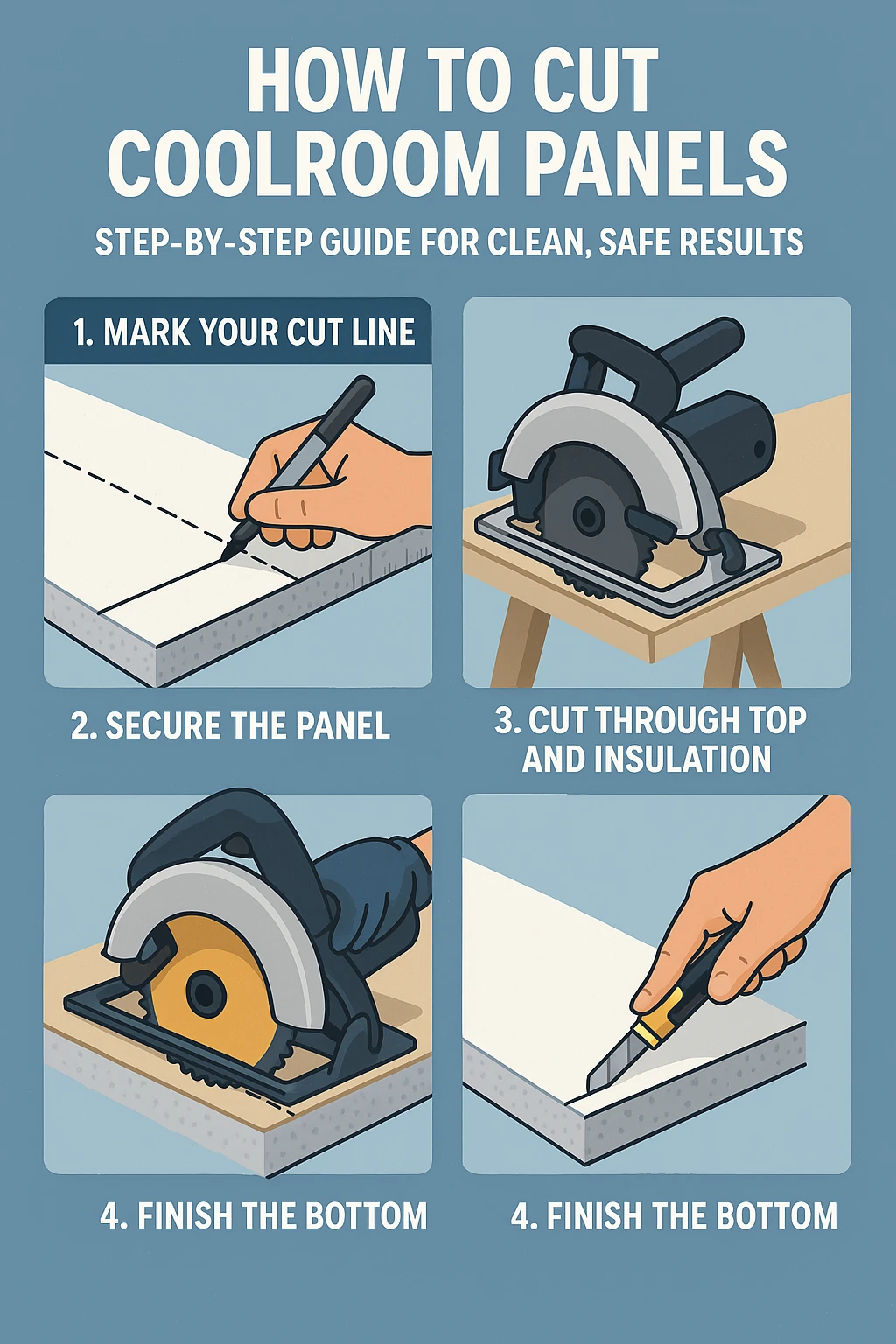

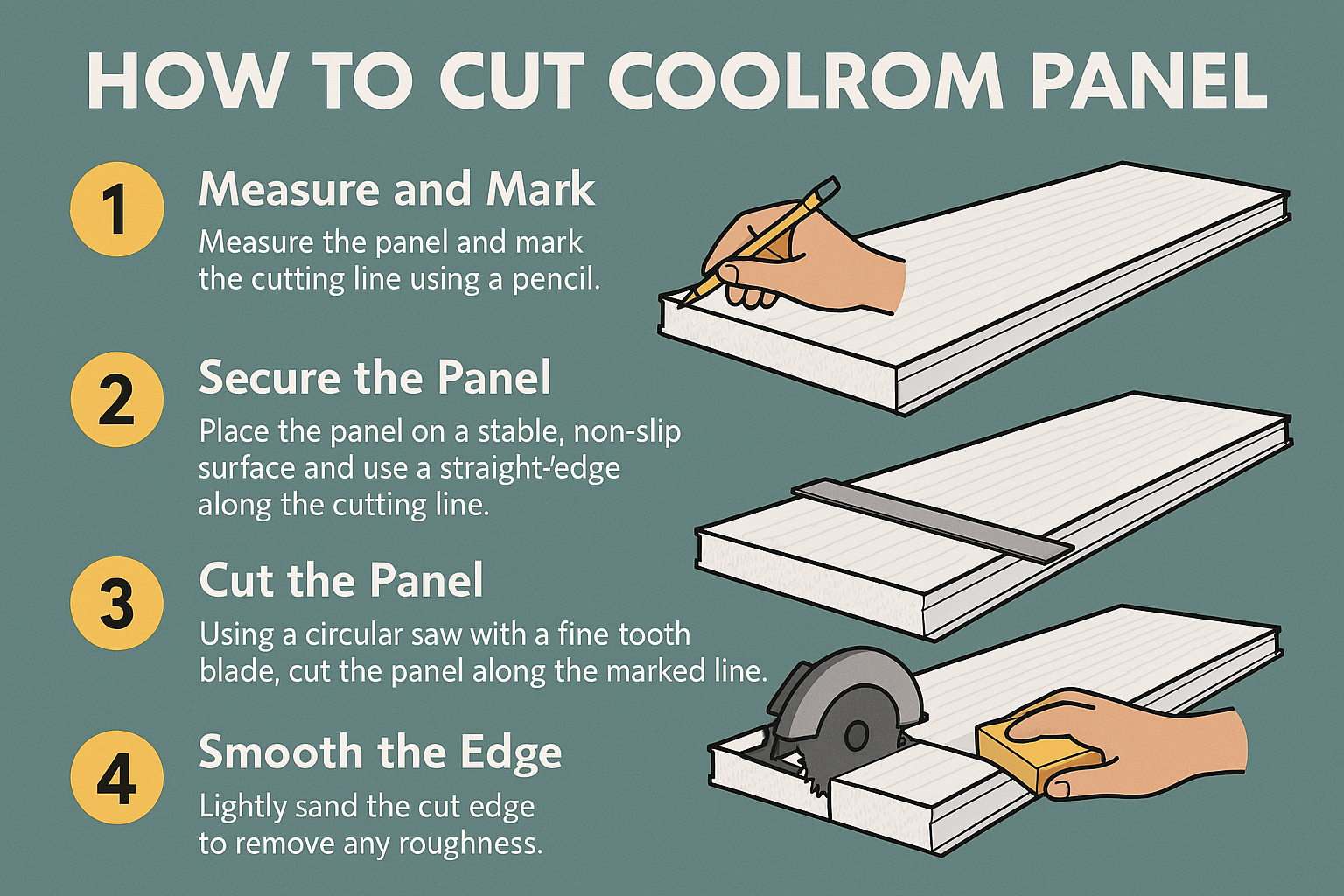

4) Step-by-Step: How to Cut Insulated Panels Cleanly

Step 1 — Plan & measure

Measure the opening, allow for joints/overlaps, and mark your cut line with a straightedge. If the panel uses a joint profile (tongue & groove, cam-lock, Z-lock), plan the cut so the joint still functions.

Step 2 — Choose the correct blade/tool

- Foam-core: fine-tooth blade for straight cuts; knife for trimming edges.

- Metal-faced: metal/composite-safe blade or shears; keep heat low.

- SIPs: a blade suited to board skins; cut slowly to avoid tear-out.

Step 3 — Clamp and support the panel

Clamp the panel and guide. Make sure the offcut is supported so it doesn’t tear the last part of the cut.

Step 4 — Make the cut (slow and steady)

- Use steady, even pressure—don’t force the blade.

- For metal skins, start on the metal face to reduce burrs and distortion.

- Stop immediately if the panel vibrates or binds—re-support and re-clamp.

Step 5 — Deburr, clean, and inspect

Remove swarf/foam dust, check the edge for burrs, and confirm the core isn’t torn or crushed. Clean cuts = tighter joints = better thermal performance.

5) How to Protect & Seal Cut Edges (This Is the Step That Prevents Problems)

After cutting, your priority is protecting the exposed edge—especially for metal-faced panels where moisture can start corrosion, and for cool rooms where edge leaks become condensation points.

- Brush/vacuum dust away (dust can stop sealants from bonding properly).

- Remove burrs and sharp edges (file lightly if needed).

- Seal exposed foam (compatible tape/coating/sealant depending on your build system).

- Protect exposed metal edges (edge protection + sealing to reduce corrosion risk).

If your project is a cool room, edge sealing works together with proper panel joining. See how to join coolroom panels.

6) Common Mistakes That Cause Wasted Panels

- Skipping “measure twice” → gaps, rework, and expensive replacement panels.

- Wrong blade/tool → chipped coatings, rough edges, crushed cores.

- No support under the cut → the panel flexes and tears at the end.

- Rushing long cuts → wandering lines and joints that won’t seal properly.

- Not sealing cut edges → moisture ingress, corrosion risk, and air leaks.

Want to estimate your panel needs before you start cutting?

Use our calculator for a quick estimate, then request a quote with your dimensions and delivery location.

Tip: If you send your opening sizes (doors, windows, penetrations), you’ll reduce site cutting and waste.

FAQ: Cutting Insulated Panels

Can I cut insulated panels on-site?

Yes—most projects cut panels on-site for final sizing and openings. The keys are: correct tool/blade, solid support, and sealing the cut edges immediately after cutting.

What’s the cleanest way to cut long, straight lines?

Use a straightedge or track/guide, clamp it firmly, and cut slowly with a suitable blade. Supporting both sides of the cut helps prevent binding and chipping.

How do I avoid damaging the metal coating?

Avoid high-heat abrasive cutting, use the correct blade/shears, and clean swarf off the panel immediately. After cutting, protect the edge so moisture can’t start corrosion.

Do I need to do anything special for cool room panels?

Cool rooms rely on airtight joints. Keep cuts square, protect the foam edge, and ensure your joint system still engages properly. For the next step, see our guide on joining panels.

Final Takeaway

Cutting insulated panels safely is mostly about control: stable support, the right blade, and edge protection. If you get those right, you’ll get cleaner joins, better insulation performance, and fewer headaches during installation.

Disclaimer: This article is general guidance. Always follow tool manufacturer instructions and applicable building/safety requirements for your site.