Cold Storage in Australia: What Thickness Coolroom Panel Do You Need?

By Cool Room Master | Updated November 2025 | Category: Coolroom Construction & Insulation

Choosing the right coolroom panel thickness is one of the most important decisions you’ll make when building cold storage in Australia. Go too thin and you’ll battle condensation, high power bills and overworked compressors. Go too thick and you may overspend on materials you don’t actually need. This guide explains when to use 50 mm, 75 mm, 100 mm and thicker panels, with practical examples for restaurants, bottle shops, warehouses and pharmaceutical facilities.

Introduction: Why Panel Thickness Matters for Australian Coolrooms

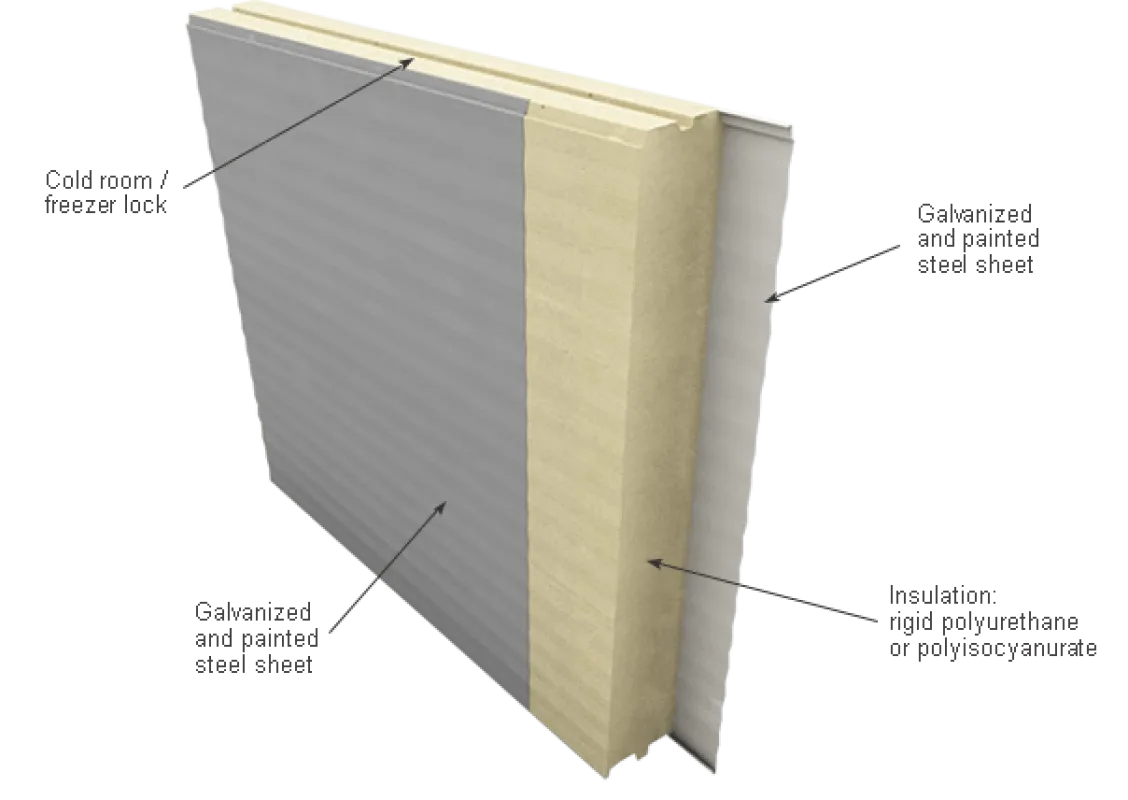

In a country that swings from scorching 40°C days to icy winter nights, insulation performance is critical. Coolroom panels do three jobs at once: they form the structure of the room, provide the thermal barrier, and create a clean, hygienic surface that’s easy to wash down.

The thickness of those panels directly influences:

- How hard your refrigeration system needs to work

- Your ongoing electricity costs

- Risk of condensation, mould and food spoilage

- Compliance with food safety and fire standards

At Cool Room Master, we design and supply insulated wall and ceiling panels for projects across Adelaide, regional South Australia and interstate. The most common question we hear is: “What thickness coolroom panel do I actually need?” – this article is your plain-English answer.

Key Principles When Selecting Coolroom Panel Thickness

1. Start With Your Temperature Range

The colder the room, the thicker your panels should be. A +4°C beverage coolroom doesn’t need the same insulation as a −20°C meat freezer. Designing from the temperature backwards ensures you’re not under-specifying or wasting money.

2. Consider Room Size and Height

Larger rooms with higher ceilings lose more energy through their envelope. They often benefit from stepping up thickness or using higher-performance cores such as PIR in the ceiling. Long spans may also need engineering checks to confirm panel strength.

3. Factor in Local Climate and Building Location

A coolroom in a climate-controlled warehouse behaves very differently to a unit sitting in a hot tin shed in regional South Australia. In harsh environments, thicker panels can prevent heat soak and compressor burnout during heatwaves.

4. Look Beyond Build Cost to Running Cost

Saving a few dollars per square metre on thinner panels can cost hundreds of dollars per month in extra power usage. Because panels last 15–30 years, it’s usually smarter to invest in better insulation upfront.

Coolroom Panel Thickness Guide: 50 mm vs 75 mm vs 100 mm+

Use the thickness guide below as a starting point. For project-specific design or span checks, you can always contact our team with your room dimensions and set temperatures.

| Panel Thickness | Typical Temperature Range | Common Australian Use Cases | Our Recommendation |

|---|---|---|---|

| 50 mm | Ambient (10°C+) | Dry storage, packaging areas, internal clean partitions, offices inside warehouses. | Great for non-refrigerated spaces. Not recommended for commercial coolrooms or freezers in Australia. |

| 75 mm | +2°C to +10°C | Restaurant and café coolrooms, bottle shops, florists, general food prep and short-term storage. | The most popular thickness. Excellent balance of material cost and energy performance for standard coolrooms. |

| 100 mm | 0°C to −20°C | Freezers, long-term meat and seafood storage, regional and remote facilities, hot warehouses. | Ideal for Australian freezers and high-load sites. Strongly recommended where reliability and low running cost matter. |

| 120–150 mm | Below −20°C / critical environments | Blast chillers, pharmaceutical storage, biotech facilities, export meat plants and high-risk manufacturing. | Premium insulation level used where strict temperature control and compliance are non-negotiable. |

Quick Rules of Thumb

- Cafés, restaurants, bottle shops: start at 75 mm.

- Freezers and mixed-use rooms: move to 100 mm or thicker.

- New builds with long operating hours: choosing a thicker panel often pays back within a few summers in power savings.

For more inspiration on how insulated panels can be used around the home and workplace, read our article 10 Innovative Uses for EPS Panels in Home Design .

EPS vs PIR Panels: Does Core Material Change the Thickness?

Thickness is only one part of the story. The core material inside your sandwich panels also affects performance, fire behaviour and compliance.

EPS (Expanded Polystyrene) Coolroom Panels

- Excellent value for money and widely used across hospitality and retail.

- Reliable insulation performance for coolrooms and many freezers.

- Ideal for projects where fire-rated construction is not specifically required.

PIR (Polyisocyanurate) Fire-Rated Panels

- Higher fire performance, with FM-approved options for critical facilities.

- Better R-value per millimetre, meaning you can sometimes use slightly thinner panels.

- Favoured in food manufacturing, pharmaceutical and cleanroom projects.

At Cool Room Master we supply both EPS and PIR fire-resistant panels in a range of thicknesses and finishes. If you’re unsure which way to go, our design team can compare options for your specific compliance requirements and budget.

How Australian Climate Changes the Thickness Equation

Many overseas coolroom guides are written for cooler European or North American climates. Australia is different: we design for extreme heat, UV exposure and humidity.

Coastal QLD & NSW

High humidity and salt air put constant pressure on refrigeration systems. Stepping up from 75 mm to 100 mm panels, particularly in the ceiling, can make a dramatic difference to ice build-up and compressor life.

Adelaide & Melbourne

Big day-night temperature swings mean coolrooms are always working to maintain balance. Good airtightness and appropriate panel thickness ensure rooms stay stable during heatwaves and cold snaps, without massive power spikes.

Regional & Remote Sites

In locations where service calls are expensive or delayed, reliability becomes the priority. Thicker panels combined with quality doors and gasketing give your system a larger safety margin when the weather turns extreme.

Thickness, Energy Bills and Lifecycle Cost

It’s easy to focus on the upfront price of panels, but the real question is: “What will this room cost me to run over the next 10–20 years?”

- A poorly insulated coolroom can burn through hundreds of extra dollars in electricity every month.

- Compressors that run constantly wear out faster, increasing maintenance and replacement costs.

- Temperature fluctuations increase the risk of product waste, especially in high-value meat and seafood.

When you factor in these lifecycle costs, upgrading from 75 mm to 100 mm or choosing PIR instead of basic foam can be one of the smartest investments in your entire project.

FAQ: Common Questions About Coolroom Panel Thickness

Is 50 mm coolroom panel thickness enough?

For most commercial cold storage in Australia, 50 mm is not enough. It can work for internal partitions or ambient rooms, but we strongly recommend at least 75 mm for coolrooms and 100 mm+ for freezers.

When should I choose 100 mm or thicker panels?

Choose 100 mm or thicker when:

- You are building a freezer or blast chiller.

- You store high-value or sensitive products such as meat, seafood or pharmaceuticals.

- Your coolroom is exposed to extreme heat or sits inside a hot shed.

- You want the lowest possible running cost and longest equipment life.

Can I mix thicknesses in the same project?

Yes. Many projects use 75 mm walls with 100 mm ceilings, or EPS for coolrooms and PIR for higher-risk freezers or fire-rated corridors. Our team can help you balance budget, compliance and performance.

Need Help Choosing the Right Thickness?

Whether you’re fitting out a small restaurant coolroom or designing a large distribution freezer, Cool Room Master can help you specify the right panel thickness, core type and span for Australian conditions.

Explore our insulated wall and ceiling panel range here: Coolroom Wall Panels — Shop Online . Or send your drawings and requirements through our enquiry form: Contact Cool Room Master .