35mm vs 50mm vs 75mm Cool Room Panels: The Ultimate Guide

When planning a new cool room or cold storage facility, one of the most critical decisions you will make is selecting the right panel thickness. This choice directly impacts everything from energy efficiency and long-term operating costs to the structural integrity and overall performance of your cool room. This comprehensive guide will compare 35mm, 50mm, and 75mm cool room panels to help you make an informed decision and ensure the success of your project.

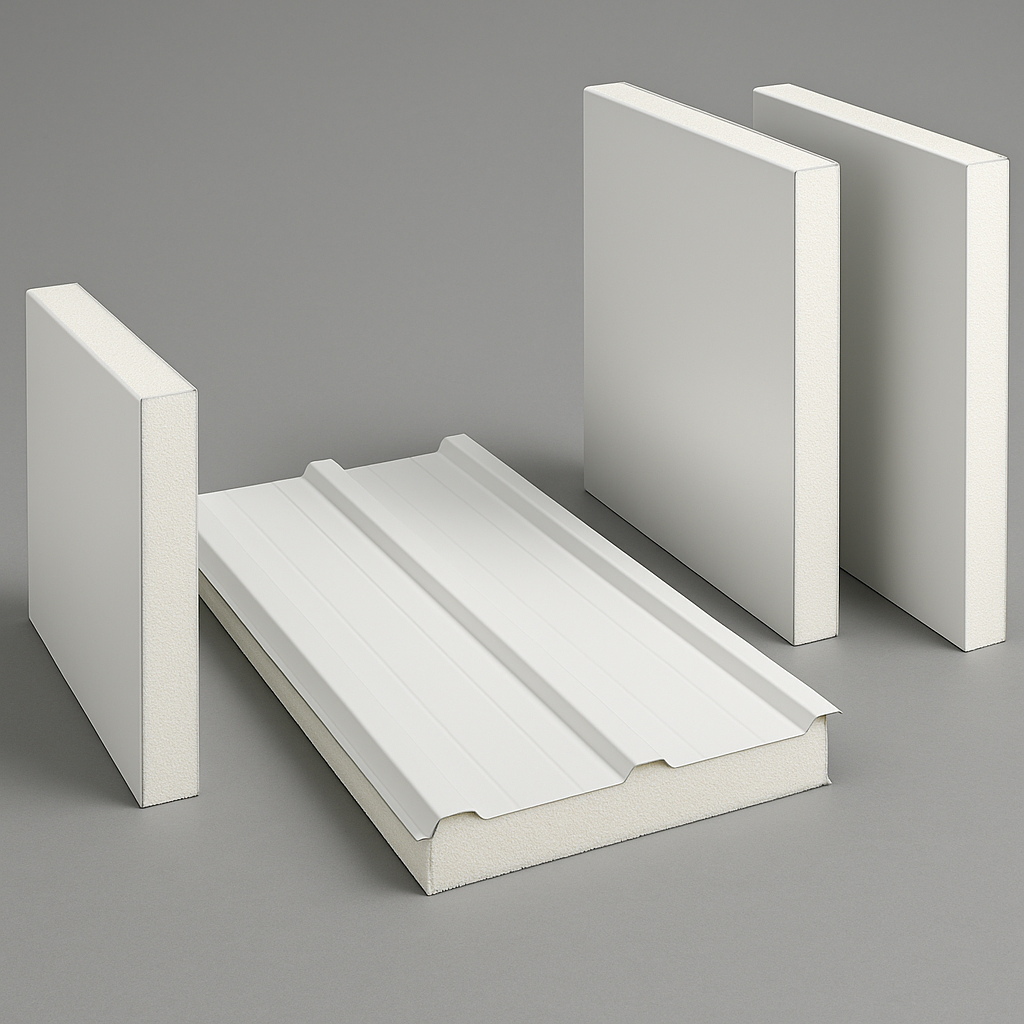

Understanding Cool Room Panel Thickness

Cool room panels, often referred to as insulated panels or sandwich panels, are the primary building material for temperature-controlled environments. They are composed of a rigid insulation core—typically Expanded Polystyrene (EPS)—sandwiched between two durable sheets of metal, such as pre-painted steel. The thickness of this insulating core is a key factor that determines the panel’s thermal resistance, also known as its R-value. A higher R-value means better insulation, which in turn reduces heat transfer and minimizes the workload on your refrigeration system. For peace of mind, it’s also important to know that our EPS panels are designed to meet Australian building codes and standards.

While thicker panels generally provide better insulation, they also come with higher costs and can take up more space. Conversely, thinner panels are more affordable and space-efficient but may not be suitable for low-temperature applications. Understanding this trade-off is essential for optimizing your cool room's performance and budget. The panels are also easy to customize—learn about the essential tools and tips for cutting cool room panels to fit your specific needs.

Deep Dive into 35mm Cool Room Panels

Our **35mm cool room panels** are the entry point into insulated construction. They are lightweight, cost-effective, and provide a reliable level of insulation for applications where minimal cooling is required. This thickness is a smart choice for projects where budget is a primary consideration and extreme temperatures are not a factor.

Ideal User Cases for 35mm Panels:

- Chiller Rooms and Walk-in Coolers: Perfect for small commercial spaces like cafes, restaurants, or bottle shops that need to maintain above-freezing temperatures (0°C to 5°C) for storing fresh produce, beverages, and dairy.

- Residential Storage: An excellent solution for building small, insulated storage sheds or wine cellars where a stable, cool environment is needed.

- Temporary or Portable Structures: Their lightweight nature makes them easy to transport, assemble, and disassemble, making them ideal for temporary event spaces or pop-up cold storage.

Advantages of 35mm Panels:

- Cost-Effective: They offer the lowest upfront cost, making them accessible for small businesses and residential projects.

- Lightweight and Easy to Install: Their low weight makes handling and installation faster and less labor-intensive.

- Space-Efficient: The thinner profile takes up less internal space, maximizing storage capacity within the room.

Deep Dive into 50mm Cool Room Panels

The **50mm cool room panel** is the most common and versatile option, striking a perfect balance between performance and cost. It provides a significant step up in thermal efficiency from 35mm panels, making it suitable for a wider range of applications. This thickness is considered the industry standard for general cold storage needs.

Ideal User Cases for 50mm Panels:

- Commercial Cold Storage: Widely used in supermarkets, butcheries, and distribution centers for large-scale cold storage of meat, dairy, fruits, and vegetables.

- Food Processing Facilities: Essential for maintaining safe, hygienic, and stable temperatures in food preparation and packaging areas.

- Medical Laboratories & Pharmacies: Ideal for creating a stable environment for storing temperature-sensitive medical supplies, vaccines, and laboratory samples.

Advantages of 50mm Panels:

- Balanced Performance: Offers excellent insulation that is a perfect fit for most cold storage requirements without the added cost of thicker panels.

- Energy Efficiency: Provides substantial energy savings over 35mm panels, leading to lower operating costs over the long term.

- Durability: The increased thickness adds to the panel's structural rigidity, making it more resistant to dents and damage. If you need to add fixtures, our guide on how to screw into cool room panels can help.

Deep Dive into 75mm Cool Room Panels

The **75mm cool room panel** is engineered for high-performance, low-temperature applications. This is the top-tier option for projects where maintaining sub-zero temperatures is non-negotiable. The substantial increase in thickness provides a significant boost in thermal resistance, making it essential for freezer rooms and other demanding environments.

Ideal User Cases for 75mm Panels:

- Freezer Rooms: The go-to choice for constructing walk-in freezers in restaurants, hotels, and industrial kitchens, capable of maintaining temperatures of -18°C and below.

- Frozen Food Warehouses: Essential for large-scale commercial storage of frozen goods, where even a slight temperature fluctuation can lead to product spoilage.

- Deep-Freeze Storage: Used in specialized facilities for storing pharmaceuticals, biological samples, and other items that require ultra-low temperatures.

Advantages of 75mm Panels:

- Maximum Insulation: Provides the highest R-value, ensuring a rock-solid thermal barrier against external heat.

- Lowest Operating Costs: By minimizing heat gain, these panels reduce the strain on your cooling units, leading to the lowest possible energy bills for sub-zero applications.

- Structural Integrity: The robust thickness makes these panels extremely strong and durable, suitable for large-scale, heavy-duty construction.

How to Choose the Right Cool Room Panel Thickness

With the advantages of each panel thickness in mind, here is a practical guide to help you make the right choice for your project.

| Factor | 35mm Panels | 50mm Panels | 75mm Panels |

|---|---|---|---|

| **Primary Use** | Standard cool rooms, chiller rooms, refrigerated display cases. | General-purpose cold storage, food processing, medical storage. | Freezer rooms, deep-freeze storage, industrial cold storage. |

| **Temperature Range** | Above freezing (e.g., +2°C to +10°C) | General refrigeration (e.g., -5°C to +5°C) | Sub-zero temperatures (e.g., -18°C to -40°C) |

| **Cost** | Lowest upfront cost. | Mid-range cost, excellent value for money. | Highest upfront cost. |

| **Energy Efficiency** | Good. | Excellent. | Maximum efficiency, crucial for low temperatures. |

| **Installation Speed** | Very fast due to lightweight. | Fast and efficient. | Slightly more time-intensive due to weight. |

| **Longevity** | Durable for intended use. | Highly durable and long-lasting. | Extremely durable for harsh environments. |

The decision ultimately comes down to your project's specific requirements, budget, and long-term goals. While a 35mm panel might save you money initially, it could lead to higher energy costs if used for an application that requires a 50mm or 75mm panel. Conversely, using a 75mm panel for a simple cool room might be an unnecessary expense. You should also consider finishing touches, such as whether you can paint cool room panels to match your branding or facility's aesthetic.

The Importance of Professional Installation and Longevity

Regardless of the thickness you choose, the performance of your cool room panels is highly dependent on professional installation. A properly installed panel system ensures every joint and seal is airtight, preventing thermal leakage and maintaining the integrity of the insulation. An improper installation, even with the thickest panels, can lead to temperature fluctuations, condensation, and wasted energy. For a detailed look at the process, see our step-by-step guide on how to join cool room panels.

At Cool Room Masters, we not only provide high-quality **35mm, 50mm, and 75mm cool room panels** but also offer expert advice and installation services. Our experienced team ensures that your cool room is built to the highest standards, guaranteeing maximum thermal performance and a long lifespan for your investment.

Proving the ROI of Your Cool Room Panels

Investing in the right panel thickness is an investment in your business’s financial health. The Return on Investment (ROI) is tangible and measurable. By selecting the correct panel, you can:

- **Reduce Energy Bills:** For every degree of temperature difference, you save a significant amount on cooling costs. Choosing a thicker panel for a freezer room can lead to thousands of dollars in savings annually.

- **Prevent Product Spoilage:** A stable temperature environment ensures the integrity of your stored goods, preventing spoilage and eliminating costly waste.

- **Minimize Maintenance:** A well-insulated cool room reduces the strain on your refrigeration system, leading to fewer breakdowns and lower maintenance costs.

The added upfront cost for a thicker panel is often recouped in energy savings within just a few years. It’s a long-term strategic decision that pays for itself many times over.

Ready to Build Your Perfect Cool Room?

Still unsure which panel is right for your project? Don't worry, our experts are here to help. Contact us today for a free consultation and let's build the ideal cool room for your needs.