Are you wondering how to paint cold room panels to keep your storage space looking fresh and functional? Choosing the right approach for painting cold room panels can enhance durability, hygiene, and aesthetics in your facility. As a cold storage professional, I understand the challenges of maintaining high-performance panels in demanding environments. That’s why I’m sharing expert tips based on real industry experience to help you get it right.

In this guide, you’ll discover the best paints for cold storage, step-by-step painting techniques, and how Cool Room Master panels make the process easier. Let’s dive in and transform your cold room!

Understanding Cold Room Panels

What Are Cold Room Panels Common Uses

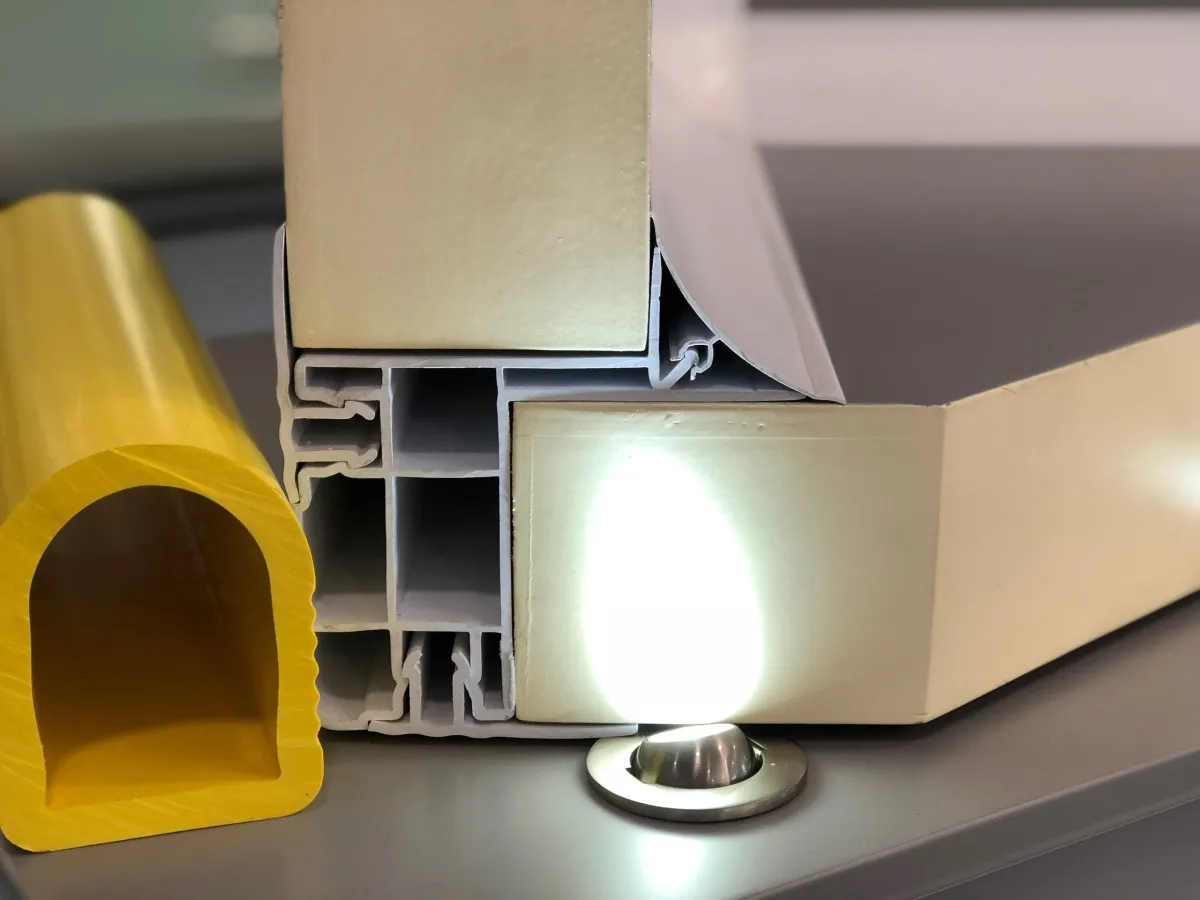

Cold room panels are insulated building components designed to maintain controlled temperatures in refrigerated spaces. They typically consist of a durable outer layer, an insulating core like polyurethane or polystyrene, and a strong inner surface. These panels are essential for creating cold rooms, walk-in freezers, coolers, and storage areas where temperature and humidity need strict control.

Common uses of cold room panels include:

- Food storage and processing facilities to keep produce fresh and safe

- Pharmaceutical and medical storage requiring stable temperatures

- Industrial cold storage warehouses for perishable goods

- Restaurants and catering businesses with walk-in refrigeration

- Supermarkets and grocery stores for display and storage areas

Their insulated design helps reduce energy consumption while providing a hygienic, easy-to-clean surface ideal for cold environments. Knowing their purpose sets the foundation for understanding why and how to paint cold room panels properly.

Why Paint Cold Room Panels

Painting cold room panels isn’t just about looks. It helps enhance the overall appearance, which can boost your brand image, especially if your cold storage is visible to customers or staff. A fresh coat of paint makes the space look clean and professional.

Beyond aesthetics, painting improves hygiene. A well-painted surface is easier to clean and less likely to harbor bacteria or mold—important in food storage or pharmaceutical environments.

Finally, paint protects the panels from corrosion and wear caused by moisture, temperature changes, and daily use. This protection extends the life of your cold room panels and keeps them functioning properly longer.

Choosing the Right Paint for Cold Room Panels

Types of Paints Suitable for Cold Room Panels

When it comes to painting cold room panels, picking the right paint is crucial for durability and performance. Here are the main types that work best:

- Epoxy Paints These are tough and offer great chemical resistance, making them ideal for cold storage environments where panels face moisture and cleaning agents. Epoxy paint also helps protect against corrosion and wear, extending panel life.

- Water-Based Acrylics If you want something low odor and more environmentally friendly, water-based acrylic paints are a solid choice. They dry faster and are easier to clean up, making them good for food-safe cold rooms where air quality matters.

- Polyester or PVDF Coatings For maximum corrosion resistance, polyester and PVDF (polyvinylidene fluoride) coatings stand out. These coatings form a strong barrier against weather and chemical damage, keeping insulated panels in top shape over time.

Choosing from these paint types depends on your cold room’s specific needs, including durability, hygiene, and environmental factors.

Choosing the Right Paint for Cold Room Panels

Key Considerations for Paint Selection

When picking paint for cold room panels, you want to focus on a few must-have qualities to get the best results:

- Temperature and Humidity Resistance Cold rooms have constant low temperatures and high moisture. The paint must hold up without cracking, peeling, or fading. Look for coatings designed to withstand extreme cold and humidity to keep your panels protected over time.

- Food-Safe or USDA-Compliant Coatings If your cold room stores food, you need paint that meets food safety standards. USDA-compliant or food-safe paints help prevent contamination and keep your cold storage environment hygienic. This is crucial for compliance and safety in food handling.

- Fire-Resistant Properties Safety first: fire-resistant paint adds an extra layer of protection. Cold rooms can contain electrical wiring and mechanical systems, so using fire-retardant coatings lowers risks and meets safety codes.

Choosing paint that ticks these boxes helps extend the life of your cold room panels, supports hygiene, and keeps your operation safe and up to code.

Choosing the Right Paint for Cold Room Panels Cool Room Master’s Recommended Products

When picking paint for cold room panels, you want products that match the panel’s unique needs. Cool Room Master offers high-quality paints designed specifically for cold storage environments. Their coatings handle temperature shifts, resist corrosion, and meet food-safe standards—key for keeping cold rooms hygienic and durable.

What sets Cool Room Master apart is their honest pricing combined with real quality. You’re not just getting paint; you’re investing in reliable protection that lasts. Their paints are fully compatible with most insulated panels, whether metal or sandwich-style, ensuring a smooth surface and strong adhesion.

Choosing Cool Room Master means better service, expert advice, and peace of mind knowing your cold room panels stay protected and looking sharp for years.

Step 1 Assess the Panel Material

Before you start painting cold room panels, it’s important to know what type of panel you’re working with. Cold room panels come in different materials like metal, polyurethane, or insulated sandwich panels, and each needs a different approach. Check if the panels already have a coating or paint—this affects what kind of paint you can use. Also, look closely for any signs of corrosion or damage that could affect how well the new paint will stick and last. Identifying these factors early helps you pick the right preparation method and ensures a smooth, long-lasting finish.

Step 2 Prepare the Surface

Before you start painting cold room panels, surface prep is key to a smooth, lasting finish. Here’s what you need to do:

- Clean the panels thoroughly: Use a mild detergent and water to remove dirt, grease, and any buildup. Dirty surfaces prevent paint from sticking properly and can lead to peeling or flaking later.

- Sand glossy or smooth surfaces: If your panels are shiny or have any old paint, lightly sand them. This creates a rough texture that helps the new paint bond better.

- Apply a suitable primer: Use a primer designed for cold room or insulated panels, ideally one that matches your paint type (like epoxy primer for epoxy paints). Primer seals the surface, protects against rust or corrosion, and improves paint adhesion.

Taking these prep steps ensures you get a strong, clean base for the paint and extend the life of your cold room panel coatings.

Step 3 Choose Application Tools

Picking the right tools makes a big difference when painting cold room panels. Here’s what works best:

- Rollers: Perfect for covering large, flat surfaces quickly and evenly. They help avoid streaks and speed up the job.

- Brushes: Best for edges, corners, and tight spots where rollers can’t reach. Use a good-quality brush to get clean lines.

- Sprayers: If you want a super smooth, even finish without brush marks, a paint sprayer is ideal. It’s especially handy for textured or detailed panels.

Choosing the right tool depends on your panel size, paint type, and how smooth you want the finish. For most room panels, a combo of rollers and brushes works well, while sprayers are great for larger projects or professional results

Step 4 Apply the Paint

Before you start, mix the paint well to make sure it’s even and smooth. Use a roller, brush, or sprayer depending on your tool choice. Apply a thin first coat—it helps the paint stick better and avoids drips or uneven spots. Don’t rush; let this first coat dry completely before adding the second layer. This step is important for durability and to protect the cold room panels from wear, corrosion, and moisture. A neat, even finish also improves the overall look and hygiene of your cold storage space.

Step 5 Inspect and Maintain

After painting your cold room panels, it’s important to check for any missed spots or uneven areas. Inspect the surface closely under good lighting to catch places that may need a touch-up. Regular maintenance will keep the paint looking fresh and protect your panels longer.

Here’s what to keep in mind for maintenance:

- Check panels regularly for chips, cracks, or peeling paint.

- Clean painted surfaces with a mild detergent and soft cloth to avoid damaging the coating.

- Avoid harsh chemicals that can break down food-safe or corrosion-resistant paints.

- Address any issues promptly to prevent corrosion or wear, especially in humid or cold environments.

Keeping up with inspection and cleaning will extend the life of your cold room panel coatings and maintain hygiene standards.

Tips for Success in Cold Room Panel Painting

Painting cold room panels takes some care to get right. Here are a few tips to make sure your job turns out great:

- Always prep the surface well: Clean panels free of dust, grease, or rust help paint stick better and last longer.

- Use the right primer: A good primer designed for metal or insulated panels prevents peeling and improves coverage.

- Choose paints made for cold storage: Look for corrosion-resistant, food-safe, and temperature-resistant options like epoxy or water-based acrylics.

- Apply thin, even coats: This avoids drips and ensures better coverage, especially on textured insulated panels.

- Paint in moderate temperatures: Too hot, cold, or humid conditions can affect drying time and finish quality.

- Use proper tools: Rollers work well for large flat panels, brushes are best for edges, and sprayers provide a smooth finish.

- Allow full drying between coats: Patience means a stronger, longer-lasting cold room panel coating.

- Maintain regularly: Clean painted panels with mild cleaners and check for any damage to protect your investment.

Following these tips will help you get a lasting, clean, and professional-looking paint job for your cold room panels.

Common Mistakes to Avoid

When painting cold room panels, avoiding these common mistakes ensures a long-lasting, effective finish:

- Skipping primer: Always use a suitable primer. It helps the paint stick better and lasts longer, especially on glossy or metal panels.

- Using non-specialized paints: Regular paints often can’t handle the cold, moisture, or chemicals in cold rooms. Choose cold room panel coatings designed for these tough conditions.

- Ignoring panel material compatibility: Different panels (metal, insulated, polyurethane) need specific paint types. Using the wrong paint can lead to peeling or corrosion.

- Painting in extreme temperatures: Too hot or too cold weather can affect paint drying and adhesion. Aim to paint when the temperature is stable and within the recommended range.

Avoiding these mistakes keeps your cold storage panels protected and looking great longer.

Why Choose Cool Room Master for Your Cold Room Needs

When it comes to cold room panels and cold storage solutions, Cool Room Master stands out for good reasons. We offer high-quality customizable panels designed to fit your specific needs, whether it’s for food storage, pharmaceuticals, or any other temperature-controlled space. Our panels deliver excellent insulation and durability, helping you maintain hygiene and prevent corrosion over time.

We believe in honest pricing and real quality—no hidden costs or shortcuts. You get the best materials and finishes, including food-safe and corrosion-resistant coatings, without breaking the bank. Plus, our team provides better service, including expert advice on selecting the right cold room panel coatings and paints, quick installation support, and maintenance tips.

If you’re ready to upgrade your cold storage with top-notch panels and expert support, reach out to Cool Room Master today. We’re here to help you keep your cold room efficient, clean, and reliable.