Can You Use Screws in Cold Room Panels? AQIS-Friendly Fixing Guide

Yes—you can screw into cold room panels, but only if you do it the right way. The wrong fastener (or poor sealing) can create air leaks, corrosion, thermal bridging, and hygiene risks. This guide explains what to use, where to screw, and how to keep your cold room airtight and durable.

What you’ll learn

- Quick answer + when screws are OK

- AQIS considerations (food-safe + corrosion resistance)

- Best screw types for cold rooms

- Step-by-step: how to screw into panels safely

- Where screws are commonly used

- Mistakes that cause leaks & condensation

- FAQ

Need panel join guidance too? Read the joining guide.

Quick Answer: Yes—But Use the Right Screws and Seal Every Hole

Screws are commonly used in cold room construction for fixing trims, joining details, door frames, brackets and accessories. The key is to choose corrosion-resistant screws, match the screw length to the panel/build-up, and keep the room airtight and moisture-tight by sealing every screw head and penetration.

AQIS Considerations: Food Safety, Corrosion Resistance, and Cleanability

Where panels are used for food handling or cold storage, fixings should be selected with hygiene and durability in mind. In practice, that means screws should resist rust, avoid trapping moisture, and help maintain a sealed, easy-to-clean surface.

- Use stainless or suitable coated screws for humid cold-room environments

- Use sealing washers or food-safe sealant so moisture can’t track into the panel

- Avoid rough, rust-prone fixings that can create contamination or maintenance issues

- Prevent condensation “cold spots” by keeping penetrations minimal and properly sealed

Best Screws for Cold Room Panels

Cold room panels typically have a rigid insulation core (often PU/PIR) with metal skins. You want a screw that can bite cleanly, resist corrosion, and maintain a sealed finish at the head.

| Screw Type | Best for | Why it works |

|---|---|---|

| Stainless steel screws | High-humidity cold rooms, wet areas, wash-down zones | Strong corrosion resistance and longer service life |

| Insulated panel screws (coated) | General panel fixing into suitable structure | Designed for sandwich panels; better bite and durability |

| Screws with sealing washers | External faces, trims, brackets, penetrations | Helps stop moisture ingress around the head |

| Self-drilling / self-tapping (panel-rated) | Metal skin applications (when appropriate) | Cleaner installation—still needs sealing and correct torque |

How to Screw into Cold Room Panels Safely (Step-by-Step)

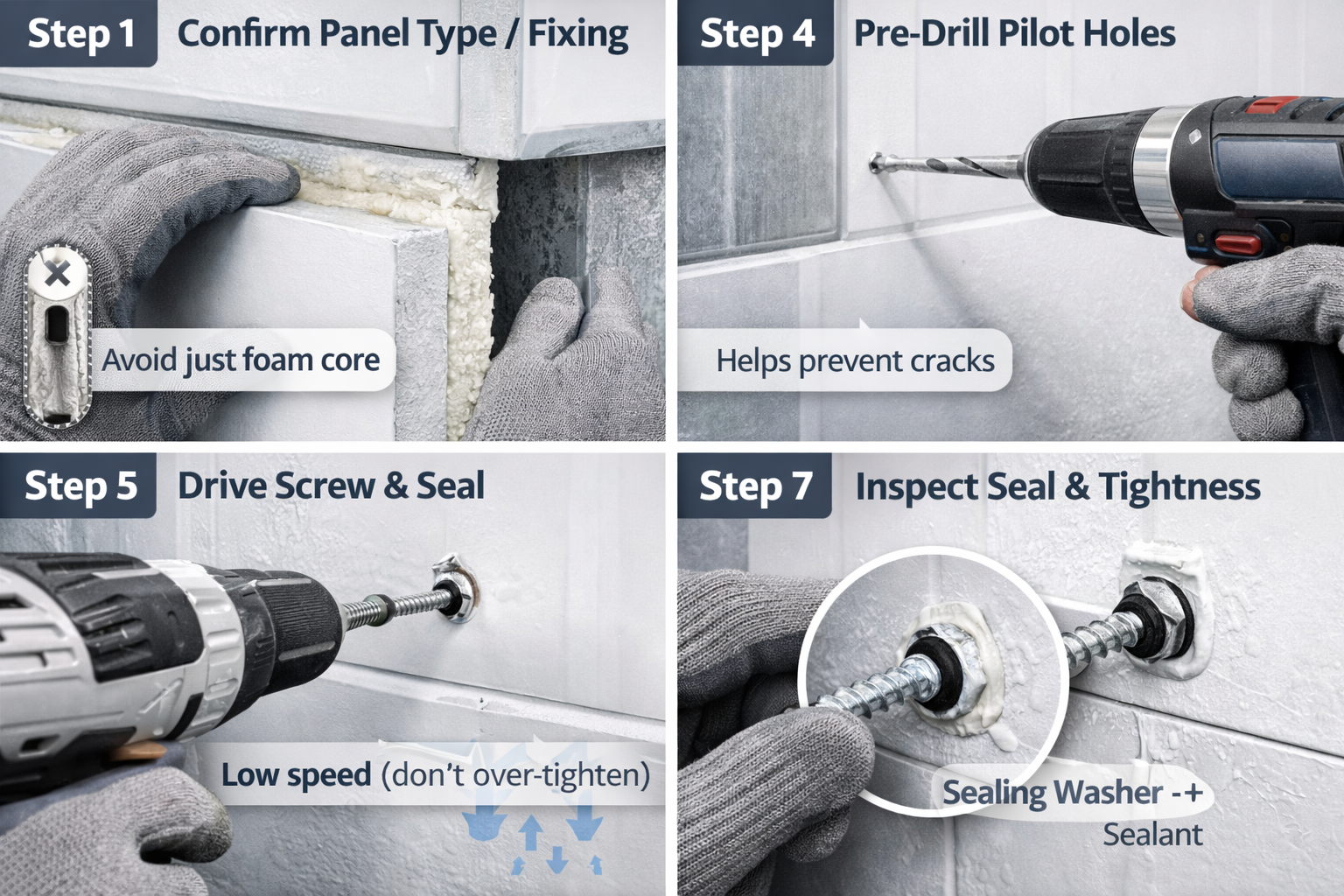

Step 1: Confirm what you’re fixing into

Whenever possible, fix into framing, joiners, brackets, or structural supports—not just foam core. This improves holding strength and reduces the risk of crushing the panel.

Step 2: Choose correct screw length

The screw should be long enough to secure the component properly, but not so long that it causes damage or creates unwanted penetrations on the opposite face.

Step 3: Mark positions and keep off edges

Plan spacing evenly and avoid placing screws too close to panel edges where skins can distort or crack.

Step 4: Pre-drill when needed

Pilot holes can reduce skin distortion and help screws go in straight—especially on metal skins and precise trim details.

Step 5: Drive screws at low speed (don’t over-tighten)

Over-tightening can crush insulation and deform skins—this creates micro-gaps that lead to air leakage and condensation.

Step 6: Seal the screw head

Use sealing washers and/or an appropriate sealant so moisture cannot track into the panel around the screw head.

Step 7: Inspect immediately

Check for gaps, wobble, crushed foam, or distortions. Fix issues now—small problems get bigger once the room is operating.

If you’re also planning to cut panels for penetrations or accessories, see: Cut cold room panels safely.

Where Screws Are Commonly Used in Cold Rooms

- Trims, flashings, and corner details

- Door frames and hardware mounts

- Brackets, clips, and support angles

- Service penetrations (only when sealed properly)

- Light-duty accessories (prefer mounting plates or brackets instead of relying on foam)

Common Mistakes That Cause Leaks, Rust, and Condensation

| Mistake | What it causes |

|---|---|

| Using non-corrosion-resistant screws | Rust, loosening, hygiene issues, premature failure |

| Skipping pilot holes on sensitive details | Panel skin distortion, uneven joints, weak fixings |

| Over-tightening | Crushed insulation, micro-gaps, thermal bridging points |

| Not sealing screw heads | Moisture ingress, leaks, condensation around fixings |

| Screws too close to edges | Warping, cracking, poor engagement at joins |

Need panels, fixings, or a quick estimate?

Use the calculator for a fast estimate, or send your room size and target temperature for practical advice.

Tip: Include panel thickness, room dimensions, door size, and delivery suburb/postcode for faster recommendations.

FAQ: Screws in Cold Room Panels

Do screws reduce insulation performance?

A few correctly installed screws usually won’t “ruin” insulation, but poorly sealed penetrations can create cold spots and condensation points. Use the right fasteners and seal everything.

Should I always use sealing washers?

For most cold-room applications, sealing washers are a smart choice—especially on external faces, trims, and any area exposed to moisture or wash-down conditions.

Can I screw directly into the foam core?

For very light items, sometimes—but it’s not ideal. For anything with meaningful load, use framing, supports, brackets, or mounting plates designed for panel systems.

How often should fixings be checked?

In commercial use, a simple inspection every 6–12 months helps spot corrosion, loosening, or sealant breakdown before it becomes a leak.

Final Takeaway

Yes, you can use screws in cold room panels—but treat every screw as a controlled penetration. Choose corrosion-resistant insulated panel screws, avoid over-tightening, and seal every fixing point to keep your cold room efficient, hygienic, and long-lasting.

Disclaimer: This article is general guidance only. Always follow your panel system specifications and site requirements.