How to Cut Cold Room Panels (PU / PIR / EPS) Without Damaging Insulation

Cutting insulated cold room panels is simple when you use the right blade, support the panel correctly, and seal the edge immediately. This guide covers tools, step-by-step cutting, edge sealing, and safety.

Related reading: Do EPS panels meet Australian building codes?

Quick Navigation

1) Understanding Cold Room Panels Before You Cut

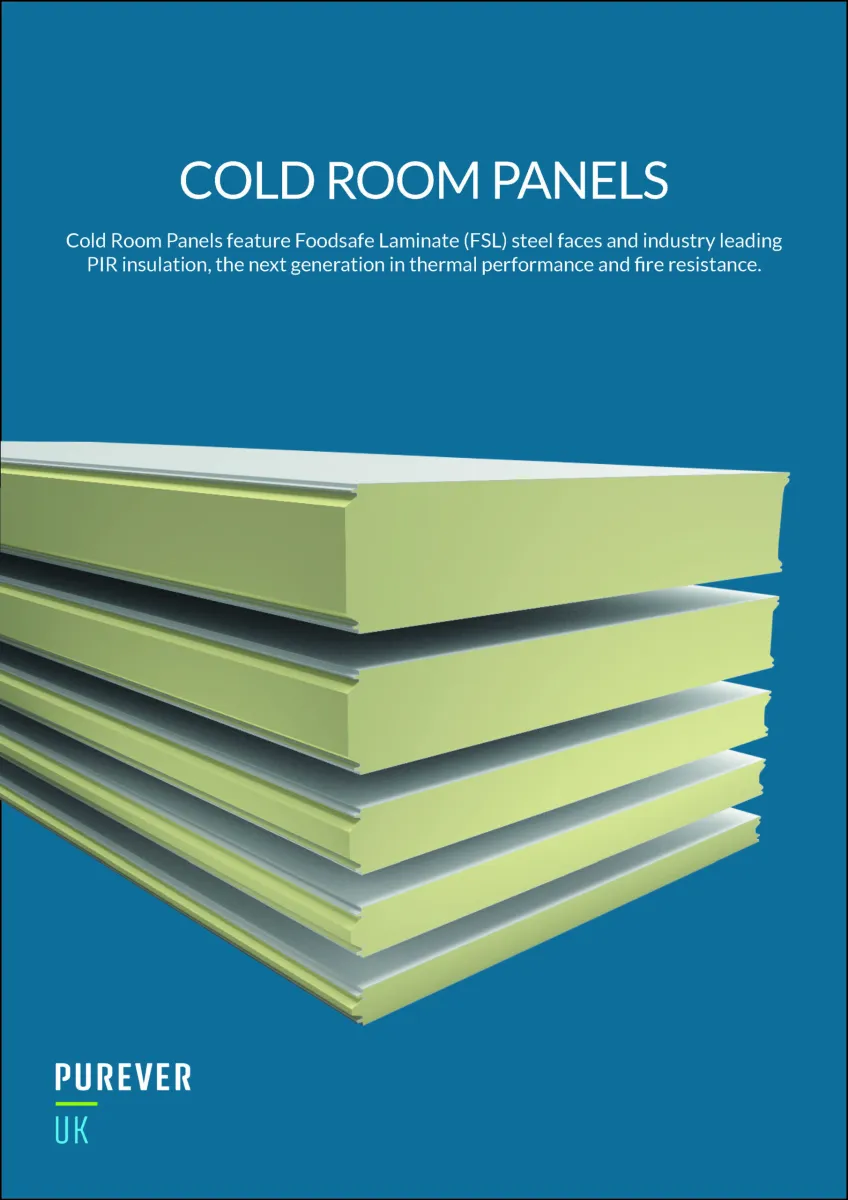

Most cold room panels are “sandwich panels”: metal skins with an insulated core. How cleanly you can cut depends on the core type (PU / PIR / EPS), panel thickness, and how well the panel is supported during the cut.

- Jagged skins = hard to seal and easier to rust.

- Crushed core = air gaps and weaker thermal performance.

- Messy joints = harder to keep hygienic and airtight.

Typical thickness guide

| Thickness | Common use | Cutting note |

|---|---|---|

| 25–50mm | Small cool rooms / light duty | Support well to avoid flex; consider scoring to reduce chipping. |

| 50–75mm | Most commercial cool rooms | Track saw or fine-tooth circular saw gives the cleanest straight cuts. |

| 75–100mm+ | Freezers / very low temps | Use the correct blade, slow feed rate, and seal edges immediately. |

2) Tools Needed for Cutting Cold Room Panels

The goal is a straight cut with minimal burrs on the metal skin and minimal tearing of the core.

Recommended tools

- Track saw (best for long straight cuts and cleaner edges)

- Circular saw with a fine-tooth blade (good all-round option)

- Jigsaw for cut-outs (use the right blade and go slow)

- Oscillating multi-tool for detail cuts around corners

- Clamps + straight edge to stop panel movement

- Vacuum / dust extractor for foam dust + swarf control

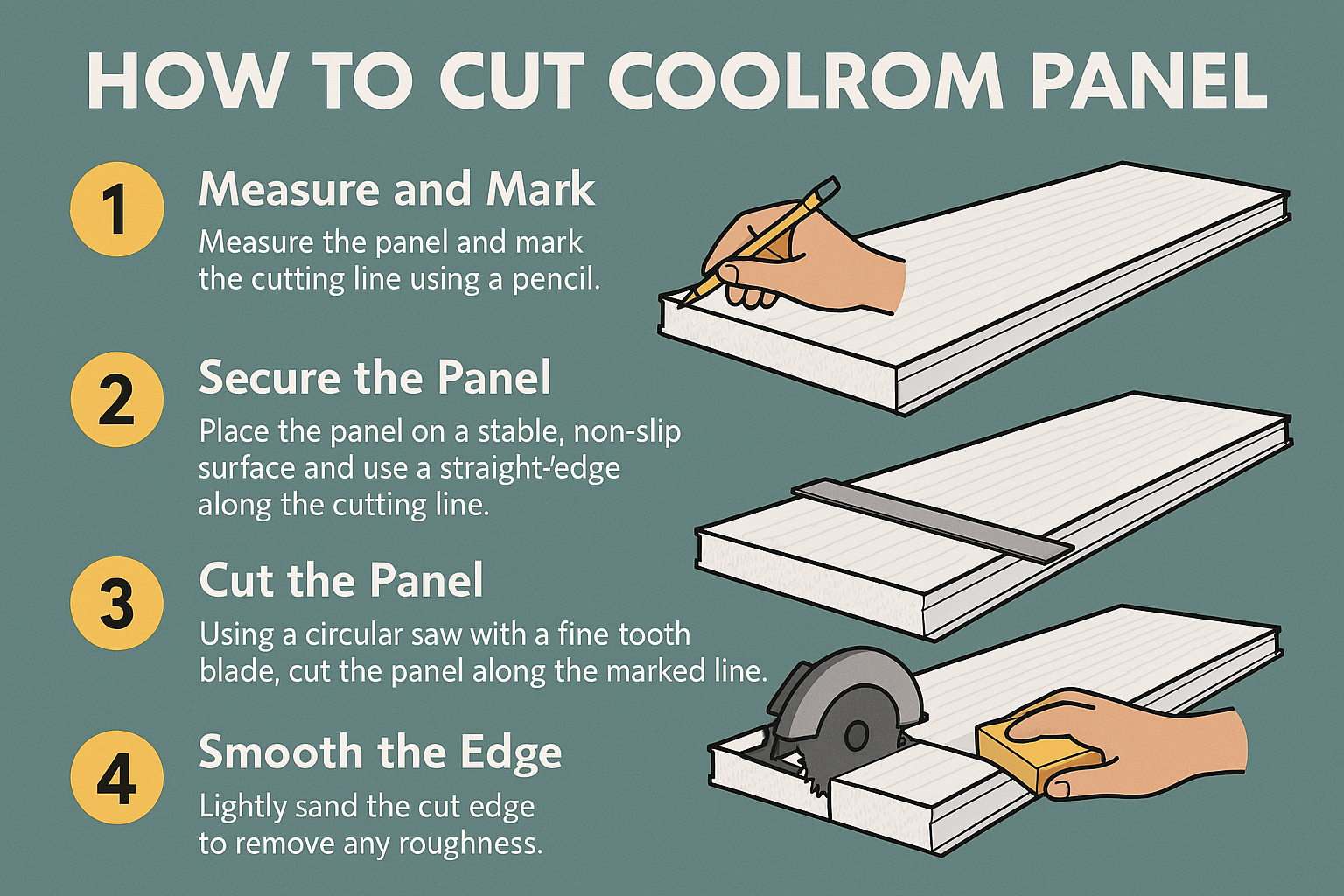

3) Step-by-Step: How to Cut Cold Room Panels Cleanly

Step 1 — Measure and mark

Measure twice, mark once. Use a straight edge for long cuts. For cut-outs (service penetrations), mark the exact opening and confirm clearance.

Step 2 — Support the panel (don’t let it flex)

Lay the panel on a flat surface with continuous support under the cut line. Flexing is what causes tearing, chipping, and crushed insulation.

Step 3 — Cut the metal skin smoothly

Start with steady feed rate. Let the blade do the work. Rushing creates burrs and heats the skin.

Step 4 — Keep the core intact

PU/PIR cores cut cleanly with the correct blade. EPS is more prone to tearing—go slower and keep support tight.

Step 5 — Seal the cut edge immediately

Any exposed core should be protected to reduce moisture ingress and maintain airtight performance. Use edge tape / sealant appropriate for cold room environments.

4) Best Practices for Professional Results

Avoid common mistakes

- Cutting on an uneven surface (panel flex = cracked skin + crushed core)

- Wrong blade / dull blade (burrs and tearing)

- Not cleaning swarf (rust spots, injuries, messy seals)

- Leaving edges unsealed (moisture ingress and performance loss)

Make airtight seals easier

- Keep cuts straight and square.

- Deburr metal edges before sealing.

- Seal edges the same day as cutting.

- Overheating the skin (fast cutting).

- Crushing foam while clamping.

- Installing panels with swarf trapped in joints.

Need panels or accessories? Browse our wall panels here: Wall Panels.

5) Safety Considerations When Cutting Cold Room Panels

- Gloves: metal skins are razor sharp after cutting.

- Eye protection: swarf can fly fast during power cutting.

- Respiratory protection: foam dust and airborne particles can be harmful.

- Ventilation + fire control: manage dust and avoid ignition sources.

Why Choose Cool Room Master for Cold Room Panels?

We supply insulated panels built for real-world cold storage—plus practical advice on installation, cutting, sealing, and accessories.

- Panels for different needs: EPS / PU / PIR options depending on budget and performance.

- Project support: guidance on cutting and sealing so your room stays airtight.

- Local help: get the right product faster with clear support.

FAQs About Cutting Cold Room Panels

What’s the best tool for cutting cold room panels?

For long straight cuts, a track saw gives the cleanest result. A fine-tooth circular saw is the common alternative. Use a jigsaw/oscillating tool for cut-outs and detail work.

Can I cut panels with a regular saw?

You can, but it usually creates rough edges, burrs, and insulation tearing. A blade designed for metal-faced insulated panels is strongly recommended.

How do I prevent insulation damage while cutting?

- Support the panel fully near the cut line.

- Use the correct, sharp blade and slow feed rate.

- Clamp without crushing the foam core.

- Seal the exposed edge immediately after cutting.

How do I choose panel thickness?

It depends on target temperature, room size, and performance needs. 50mm is common for many cool rooms; 75–100mm+ suits freezers and lower temps. If you’re unsure, contact us and we’ll help you select the right option.