Fridge Panels in Australia: The Ultimate Guide to Efficient Cool Rooms

Choosing the right fridge panel is the single biggest lever you have to improve cool room efficiency, food safety, and running costs. This in-depth guide explains panel types (EPS, PU, PIR), thickness, installation, pricing, and pro tips—tailored for Australian conditions.

What Is a Fridge Panel?

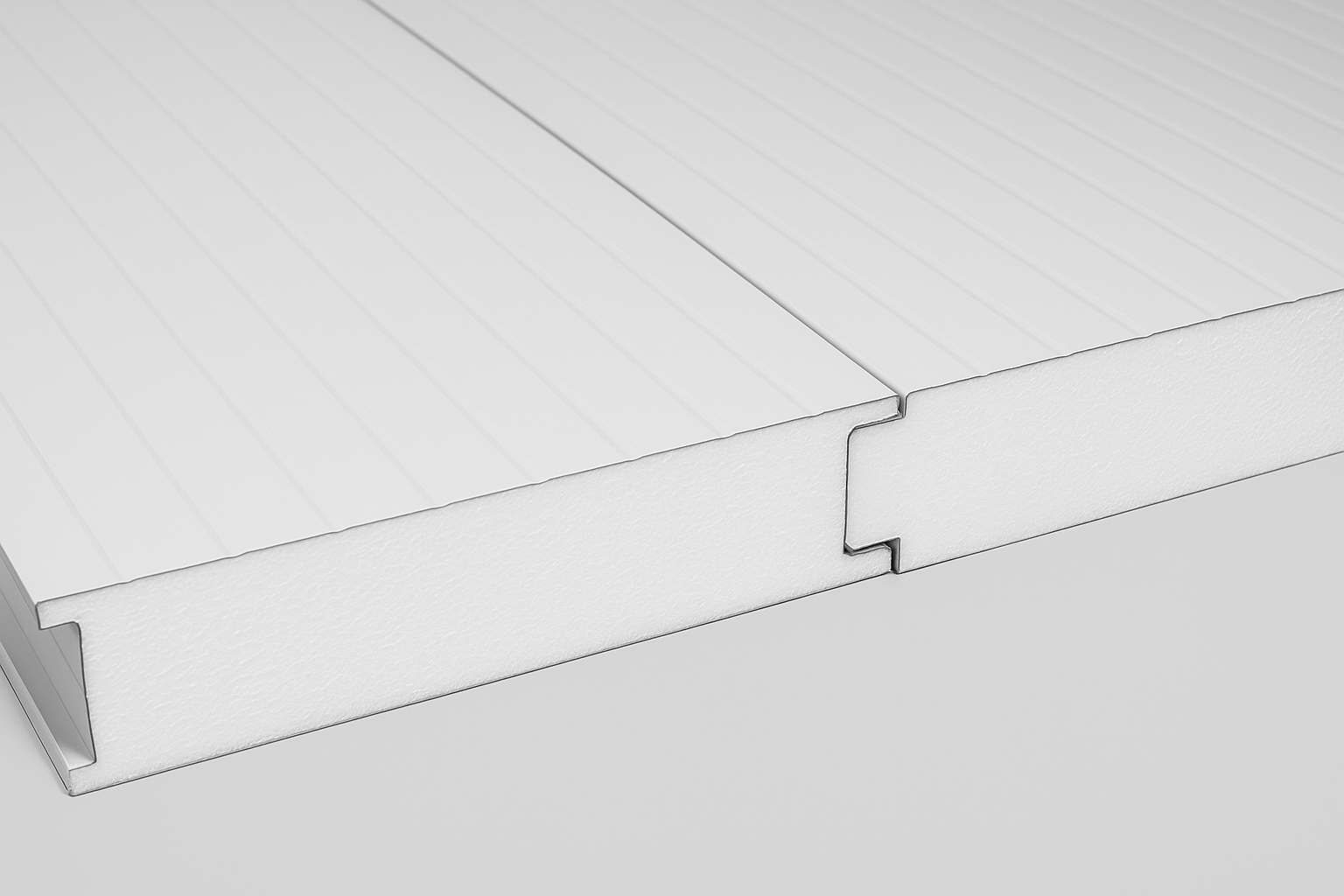

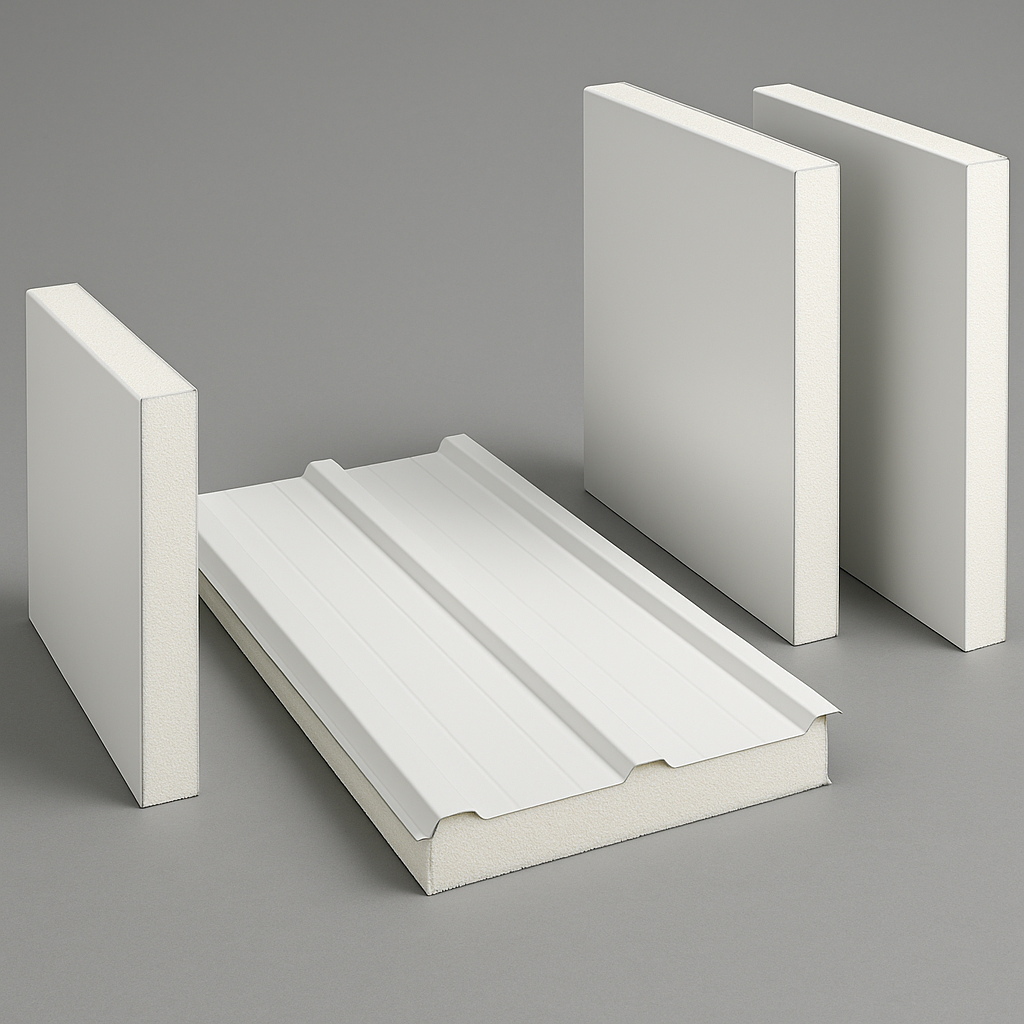

A fridge panel is a prefabricated insulated sandwich panel—rigid core (typically EPS, PU, or PIR) laminated between hygienic, corrosion-resistant steel skins. Panels lock together via tongue-and-groove or cam-lock systems to create air-tight walls and ceilings for cool rooms and freezers.

- Core materials: Expanded Polystyrene (EPS), Polyurethane (PU), or Polyisocyanurate (PIR).

- Skins: Food-grade coated steel; stainless available for harsh or high-washdown zones.

- Joints: Interlocking profiles designed to limit thermal bridging and vapor ingress.

Building a new room? Explore our cool room installation service for end-to-end supply and build.

Why Fridge Panels Are the Smart Choice

Energy Efficiency

High R-values reduce compressor load and electricity bills—especially important with Australian energy prices.

Food Safety & Hygiene

Non-porous skins and sealed junctions meet HACCP expectations; easy to clean and maintain.

Fast, Modular Build

Panels arrive cut-to-length, install quickly, and minimise downtime for hospitality and retail sites.

Scalable & Relocatable

Unlike masonry, a panelised room can be extended or partially relocated as your business grows.

Need parts to complete your build? Browse aluminium channels & trims for hygienic corners, coving, and door frames.

Types of Fridge Panels (EPS vs PU vs PIR)

The core you select determines thermal performance, fire behaviour, and cost. Here’s how the common cores compare in real-world Australian projects.

| Feature | EPS Fridge Panel | PU Fridge Panel | PIR Fridge Panel |

|---|---|---|---|

| Thermal Performance | Very good—excellent value per m² | Higher R per mm than EPS | Similar to PU, often slightly better |

| Fire Behaviour | Requires correct detailing and skins | Improved vs EPS | Best of the three (commonly specified) |

| Cost | Most budget friendly | Mid-to-premium | Premium |

| Best Use | General cool rooms | Freezers & energy-sensitive areas | Industrial, strict compliance sites |

For most cafes, butchers, and grocers, EPS wall panels offer the best price-to-performance ratio. For sub-zero freezers, PU or PIR often pays back via lower energy use.

How Thick Should My Fridge Panels Be?

Thickness drives thermal performance. As a rule of thumb: the colder the room (or the hotter the climate/plant room), the thicker your panel should be. Below are common selections our team specifies in Adelaide, Melbourne, and Sydney.

| Application | Typical Range | Popular Choices | Notes |

|---|---|---|---|

| Chillers (0–5 °C) | 50–100 mm | 75 mm EPS | Great balance of cost & performance for hospitality/retail. |

| Cool Rooms (2–8 °C) | 50–100 mm | 50–75 mm EPS | Consider 75 mm if ambient is hot or doors cycle frequently. |

| Freezers (≤ −18 °C) | 100–150 mm | 100–125 mm PU/PIR | Thicker panel lowers compressor run time and icing risk. |

| High-washdown/Harsh | 75–125 mm | PU/PIR with stainless skins | For seafood, abattoirs, and pharma clean-downs. |

Want a deeper dive on thickness trade-offs? Read our comparison: 35 mm vs 50 mm vs 75 mm cool room panels.

Common Use Cases in Australia

Hospitality

Walk-in coolers, keg rooms, pastry fridges. Frequent door openings—specify quality doors and consider 75 mm wall thickness.

Retail

Butchers, grocers, bakeries. Hygiene trims and coving are essential—see aluminium channels.

Industrial & Logistics

Dock coolers, cross-docks, and freezer warehouses—PIR/PU cores shine at scale.

Healthcare & Pharma

Vaccine and specimen storage. Consider stainless skins and PIR for performance and compliance.

Installation: Best Practices for Airtight Performance

A great panel still underperforms if the detailing is poor. Follow these field-tested practices or lean on our professional installation team.

- Flat, level substrate: Floor/curb must be plumb; use vapour barriers where required.

- Correct jointing: Engage tongue-and-groove fully; cam-locks must be tensioned evenly.

- Hygienic trims: Install aluminium channels and coving to eliminate dirt traps.

- Penetration sealing: Route pipes/conduits cleanly; seal with food-safe silicone or PU sealant.

- Doors & heaters: For freezers, test door heaters and verify defrost cycle before handover.

- Commissioning: Pressure-test, then record baseline temps/energy for ongoing benchmarking.

Handy how-tos: join panels step-by-step · cutting tips · fastening into panels · painting panels

How Much Do Fridge Panels Cost?

Pricing depends on thickness, core type, skin finish, and order volume. As indicative supply ranges in Australia:

- EPS fridge panels: ~ $60–$90 per m²

- PU/PIR fridge panels: ~ $90–$150+ per m²

Factor in trims, doors, transport, and installation. While PU/PIR costs more up front, freezers often recoup the difference with lower energy spend.

For an itemised quote (cut-to-length panels, trims, delivery), request pricing via our contact form.

Operational Tips to Lower Running Costs

Door Discipline

Specify quality doors and auto-closers; consider air curtains for high-traffic openings.

Seal Integrity

Inspect gaskets quarterly; re-seal panel joints as needed to prevent warm-air infiltration.

Condenser Hygiene

Clean coils to keep COP high—dirty coils can add 10–20% to energy use.

Data Logging

Log temperature/energy after handover to catch drift early and prove compliance.

Need help with upkeep? See our repairs & maintenance service for scheduled care and call-outs.

Maintenance & Cleaning for Long Service Life

- Cleaning: Use non-abrasive, food-safe detergents; avoid harsh solvents that can attack coatings.

- Impact protection: Install bump rails where trolleys/forks operate; dents reduce panel integrity.

- Condensation control: Check vapour seals, floor junctions, and drains to avoid moisture ingress.

- Annual audit: Re-seal joints, check roof penetrations, and test door heaters/closers.

Fridge Panel FAQs

What’s the difference between a fridge panel and a standard insulated panel?

“Fridge panel” generally refers to food-safe, cold-storage-rated sandwich panels with tight joints and hygienic finishes. Wall cladding SIPs for buildings may not meet the hygiene or vapor-control needs of cool rooms.

Do I need EPS, PU, or PIR?

For most chillers and general cool rooms, EPS is excellent value. For freezers or high-compliance sites, PU or PIR typically wins on performance and lifecycle cost.

How thick should I go?

As a guide: 50–75 mm for cool rooms; 100–125 mm for freezers. Ambient heat, door cycles, and duty cycle may shift you thicker. We’ll size it for you.

Can I retrofit my existing room with new panels?

Often yes. We can replace damaged sections, add coving, upgrade doors, and improve vapor control without a full rebuild.

Do you cut panels to length and supply trims?

Yes—cut-to-length supply, matched aluminium channels, doors, and hardware, delivered Australia-wide.

Related Guides & How-Tos

Ready to Specify Your Fridge Panels?

From small café cool rooms to national freezer warehouses, Cool Room Masters supplies and installs high-performance fridge panels Australia-wide—cut-to-length with matching trims and doors.