Exterior Wall Roof Series

Selectable surface effects

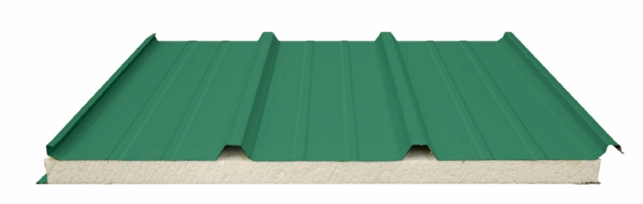

Technical parameter

Efective width: 1000mm

Thickness: 50-200mm

Length: The user needs to specify the size, and the length can reach 24 meters or even longer.

Core material: PIR 40-50KG/m³

Outer panel: 0.5-0.8mm Inner panel 0.4-0.6mm

The core material is composed of two layers of metal plates and an organic diisocyanate or polyisocyanate polymerized with dihydroxy or polyhydroxy

compounds.

The insulation material is formed in one go on the assembly line using advanced mixed casting continuous foaming technology. Low water absorption rate, high compressive strength, excellent thermal insulation efect, and no decay.

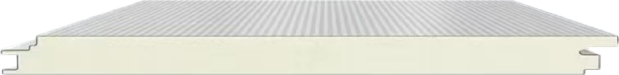

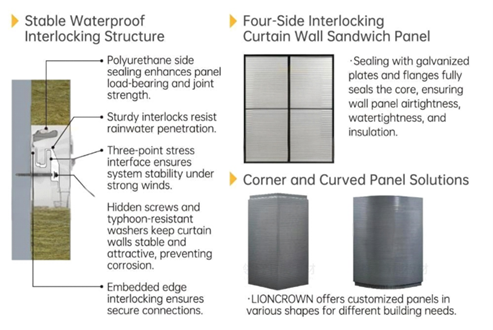

1000 type PIR exterior wall panel

Applicable industries

Exterior wall systems for large steel-structure workshops, high-tech factories, pharmaceutical facilities, logistics centers, aerospace and automotive industries, electronics manufacturing, energy R&D facilities, smart factories, ski resorts, large supermarkets, metal curtain wall projects, and other major public buildings.

Detailed description

Polyurethane wall energy-saving panels are ideal for use as exterior cladding on building roofs. These panels offer outstanding thermal insulation, heat resistance, and soundproofing. Additionally, polyurethane is non-combustible, meeting modern fire safety standards. The material is injected at the joints, giving the panels excellent strength and rigidity. The bottom surface is smooth and flat with clean lines, enhancing the indoor aesthetic and creating a sense of visual fullness. Easy to install with a short construction period, these panels represent a new generation of building materials that combine performance with visual appeal.

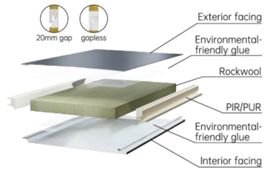

1000 type Rockwool exterior wall panel

Applicable industries

Large steel structure workshop exterior walls, high-tech factories, pharmaceutical industry, logistics indusry, aerospace indusry, automotive indusry, electronic technology, energy research and development, small factories, large supermarkets, metal wall engineering, large public buildings, etc.

Technical parameter

Efective width: 1000mm

Thickness: 50-150mm

Length: Production according to user demand for specific dimensions.

Core material: rockwool 100-180KG/m³

Product features

Polyurethane interface edge sealing, with high-density rock wool in the middle. Combining the non flammability, high temperature resistance, and stable chemical properties of rock wool with the non absorbent and heat-insulating properties of polyurethane to better integrate them together. Fireproof, good sound absorption, low thermal conductivity, non absorbent, non rotting, and quick installation.

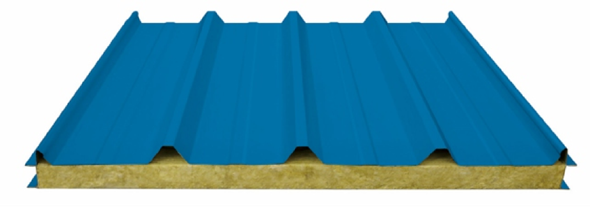

Technical parameter

Efective width: 960mm 960 type roof sandwich panel

Thickness: 50mm-150mm (according to customer requirements)

Length: customized production according to user needs, engineering requirements, and transportation conditions

Core material options: EPS, rockwool , polyurethane, XPS, rock wool, Propor, etc

Installation structure: male and female joint splicing with cover for waterproof installation

960 type rockwool roof panel

Applicable industries

Large-span composite steel and grid structures, ideal for roofs of venues, theaters, large factory buildings, conference centers, auditoriums, and other key sections of industrial facilities.

1050 type EPS roof panel

Applicable industries

Large-span composite steel and grid structures, ideal for roofs of venues, theaters, large factory buildings, conference centers, auditoriums, and other key sections of industrial facilities.

Technical parameter

Efective width: 1050mm

Thickness: 30mm-200mm (according to customer

requirements) Length: customized production according to user needs, engineering requirements, and transpo比ation conditions

Available core materials: EPS, polyurethane, XPS, rock wool, Propor, etc

Installation structure: bite type overlap.

drop us a line

Your email address will not be published. Required fields are marked *

Let’s Start Working Together

location

75 South Terrace, Wingfield, SA 5013