Are you wondering what cold room panels are made of and how to choose the best ones for your business? Selecting the right cold room panels can transform your storage, keeping products fresh and energy costs low. As a leading provider, Cool Room Master knows that quality materials are the backbone of any reliable cold storage solution. In this guide, we’ll uncover the materials behind cold room panels, their benefits, and expert tips to help you make a smart choice. Dive in to discover how our honest pricing and real quality can elevate your cold storage game!

Core Components of Cold Room Panels The Sandwich Panel Structure

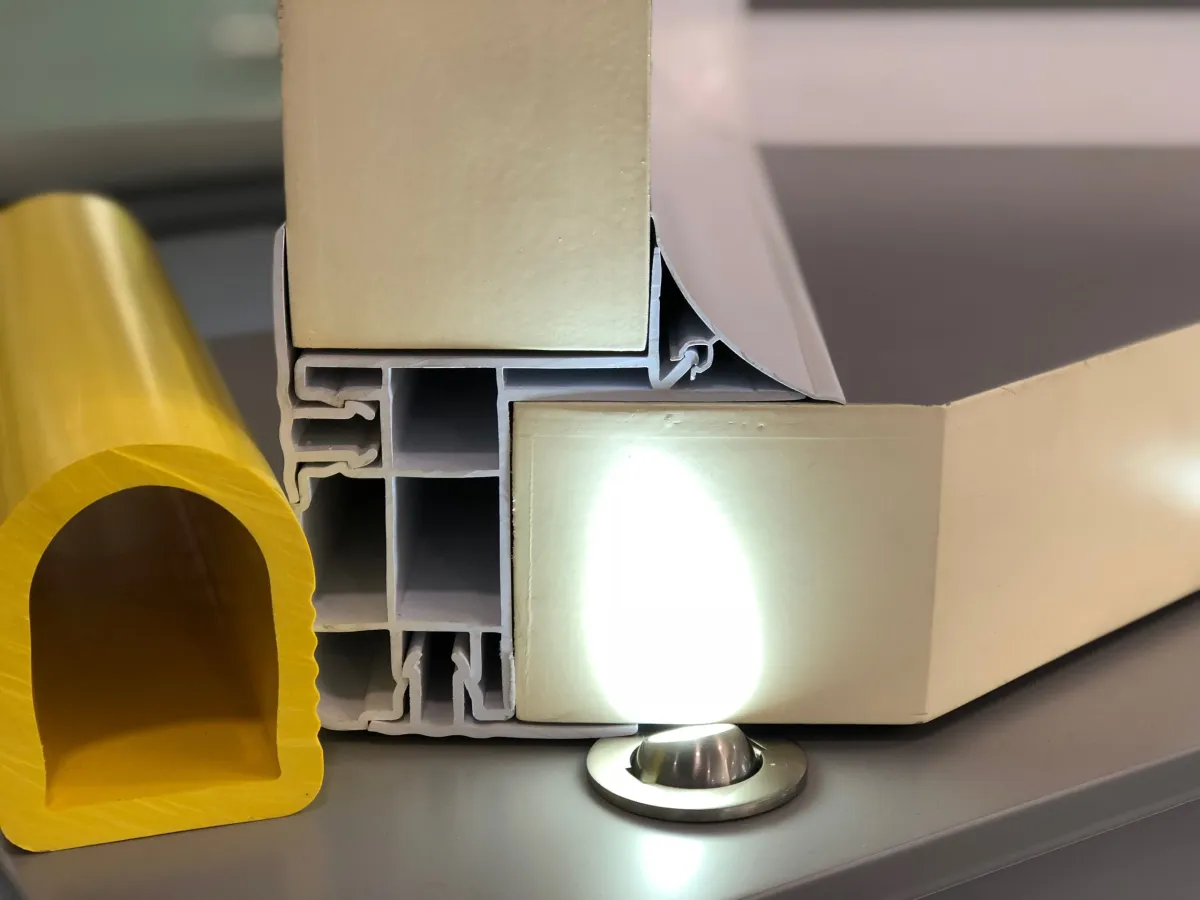

Cold room panels are built using a sandwich panel structure, which is essential for providing strong insulation and durability. This design consists of three main layers: an insulating core material sandwiched between two outer skins. The sandwich panel structure ensures excellent thermal performance while maintaining structural integrity.

Here’s how it works:

- Inner Core: The heart of the panel, usually made from insulating materials that keep cold in and heat out.

- Outer Skins: Protective layers made from materials like steel or aluminum that shield the core and provide strength.

- Bonding: The core and outer skins are securely bonded to form one solid panel, which helps prevent moisture and air leaks.

This layered approach creates panels that are lightweight yet strong, easy to install, and highly efficient at controlling temperature. It’s the foundation behind all cold room panel materials, ensuring energy efficiency and long-lasting performance.

Core Components of Cold Room Panels Common Core Materials Polyurethane PU

Polyurethane (PU) is one of the most popular core materials used in cold room panels across the US. It’s a foam insulation that offers excellent thermal resistance, helping keep cold rooms energy-efficient and stable. PU panels are lightweight but strong, making them easy to handle and install without sacrificing durability.

Polyurethane cold room panels have a closed-cell structure, which means they don’t absorb moisture—this helps prevent mold and keeps the insulation effective over time. They are also good at withstanding temperature fluctuations, making them ideal for food storage, pharmaceuticals, and other sensitive goods.

Because these panels come in various thicknesses—commonly 25mm, 50mm, or 75mm—you can pick the right level of insulation depending on your cold room’s specific needs and budget. Plus, they’re widely available from manufacturers and suppliers across states like California, Texas, and Florida, so finding a local source is usually easy and affordable.

Common Core Materials Polyisocyanurate PIR

Polyisocyanurate, or PIR, is a popular core material used in cold room panels. It offers excellent thermal insulation, often better than standard polyurethane panels, making it a top choice for energy-efficient cold storage in the U.S. PIR panels help keep temperatures stable, lowering energy costs over time.

Besides insulation, PIR is known for strong fire resistance. This is crucial for meeting safety codes, especially in commercial and industrial cold rooms. It also handles moisture well, so the panels stay durable without losing performance, even in humid environments.

If you’re looking for cold room insulation types that combine energy savings with safety, PIR insulation panels are a smart pick. They come in different thicknesses, like 25mm or 50mm, letting you tailor the panel to your specific needs. Many manufacturers across states like Texas, California, and New York offer PIR panels ready for quick installation in warehouses, food storage sites, and pharmaceutical facilities.

Common Core Materials Expanded Polystyrene EPS

Expanded Polystyrene (EPS) is one of the popular core materials used in cold room panels. It’s a lightweight, rigid foam made from expanded beads, known for its good thermal insulation properties. EPS panels help keep cold rooms energy-efficient by reducing heat transfer, which is essential in maintaining consistent temperatures.

EPS is cost-effective, making it a favorite for many businesses looking for affordable insulation without compromising performance. It also has good moisture resistance, which helps avoid damage from condensation inside the cold room.

While EPS doesn’t have the highest fire resistance compared to other core materials, it meets many building code requirements when used correctly. It’s important to source EPS panels from trusted manufacturers to ensure quality that fits the needs of your cold storage space.

If you want to check out various EPS cold room panels, you can explore options like these EPS panels for sale designed for durability and efficient insulation.

Core Components of Cold Room Panels Common Core Materials Mineral Wool

Mineral wool is a popular core material used in cold room panels thanks to its excellent fire resistance and sound insulation properties. Made from natural rock or recycled slag, mineral wool offers strong thermal insulation while standing up well to high temperatures. It’s a great choice when fire safety is a priority, especially in commercial or industrial cold storage.

Besides insulation and fire resistance, mineral wool is resistant to moisture and won’t easily rot or degrade over time, which helps maintain panel performance. If you need cold room insulation types that are durable and safe, mineral wool panels are definitely worth considering for your project.

They pair well with steel or aluminum outer skins, creating sturdy, long-lasting cold room panels suited for harsh environments, especially in places like warehouses or pharmaceutical storage in the U.S.

Common Core Materials Compressed Straw Core

Compressed straw core is an eco-friendly option for cold room panels. It’s made by tightly compacting straw fibers, creating a natural sandwich panel core. This material offers good thermal insulation and is lightweight, making it easier to handle during installation. While it may not match the fire resistance of synthetic cores like polyurethane (PU) or polyisocyanurate (PIR), compressed straw provides a sustainable alternative for those looking to reduce environmental impact. It’s especially popular in locations focused on green building practices and energy-efficient cold storage solutions. Keep in mind that proper treatment and sealing are needed to prevent moisture damage, ensuring durability and long-term performance in your cold room.

Core Components of Cold Room Panels Outer Skin Materials Steel Galvanized Stainless or Pre-Painted

The outer skin of cold room panels plays a crucial role in protecting the core insulation and ensuring the panel’s durability. One of the most common outer skin materials used in the US is steel, available in galvanized, stainless, or pre-painted finishes.

Galvanized steel is coated with zinc to prevent rust and corrosion. It’s a popular choice because it offers excellent strength at a reasonable cost and stands up well to moisture, which is vital for cold room environments.

Stainless steel panels provide superior corrosion resistance, especially in harsh settings like food processing plants or pharmaceutical storage where hygiene is critical. Though pricier, stainless steel lasts longer and requires less maintenance.

Pre-painted steel offers extra protection and aesthetic options. The factory-applied coating adds a vibrant, durable finish that resists scratches and fading while still safeguarding against moisture and rust.

Using steel outer skins on cold room panels ensures:

- Strong structural support

- Resistance to wear and tear

- Protection against environmental elements

- Easy cleaning and maintenance, important for sanitary spaces

If you’re looking to buy cold room panels, steel outer skins give you a reliable, long-lasting exterior that suits various commercial and industrial refrigeration needs across the US.

Outer Skin Materials Aluminum

Aluminum is a popular choice for the outer skin of cold room panels because it’s lightweight, corrosion-resistant, and easy to work with. It offers a sleek finish and holds up well in humid or wet environments, which is common in cold storage settings. Aluminum panels also provide good durability without adding too much weight, making installation easier and faster.

While not as strong as steel, aluminum’s resistance to rust means less maintenance over time. It’s often used in places where hygiene is key, like food storage and pharmaceutical cold rooms, because it’s easy to clean and doesn’t react with moisture or chemicals.

If you want a corrosion-resistant, lightweight option for your cold room panels, aluminum skins are a solid pick, especially when combined with effective core insulation like polyurethane or PIR. For reliable aluminum cold room panels and more options, check out our shop.

Outer Skin Materials PVC or Composite Coatings

Cold room panels often use PVC or composite coatings for their outer skin. These materials offer an extra layer of protection against moisture, corrosion, and physical damage, which helps keep the panels durable in tough environments. PVC coatings are lightweight, easy to clean, and resistant to chemicals, making them a practical choice for places like food processing facilities or pharmaceutical storage. Composite coatings combine different materials to improve strength and weather resistance, adding to the panel’s lifespan.

These coatings also contribute to maintaining the panel’s thermal performance by preventing water absorption and reducing surface wear. Plus, they offer a smooth finish that’s easy to maintain, which is crucial for hygiene in cold storage. Using outer skins with PVC or composite coatings can help ensure your cold rooms stay efficient, clean, and long-lasting under everyday wear and tear.

Key Properties of Cold Room Panel Materials

Thermal Insulation

Thermal insulation is the most important property of cold room panels. It keeps the cold in and the heat out, helping maintain steady temperatures inside the cold room. Good insulation means your cooling system doesn’t have to work overtime, which saves energy and cuts costs.

Materials like polyurethane (PU), polyisocyanurate (PIR), and expanded polystyrene (EPS) are popular because they offer excellent thermal resistance. Typically, thicker panels provide better insulation—common thicknesses range from 25mm up to 75mm depending on the cooling needs. Mineral wool also offers decent insulation but is often chosen when fire resistance is a priority.

Choosing the right panel material with strong thermal insulation ensures your cold storage stays efficient, whether you’re storing food, pharmaceuticals, or other sensitive products. It’s essential for energy-efficient cold room solutions that meet US standards and save you money long term.

Key Properties of Cold Room Panel Materials Fire Resistance

Fire resistance is a crucial factor when choosing cold room panel materials. Materials like mineral wool and PIR insulation panels offer excellent fire-retardant properties, helping slow down the spread of flames. This is especially important in commercial and industrial settings where safety regulations are strict. Polyurethane (PU) and expanded polystyrene (EPS) panels, while great for insulation, generally have lower fire resistance unless treated with special fire-retardant coatings.

When selecting cold room panels, look for certifications that confirm fire resistance. Steel or aluminum outer skins also add a layer of protection against fire damage. Overall, panels with strong fire-resistant qualities help protect your facility, contents, and people, giving peace of mind along with thermal efficiency.

Durability and Moisture Resistance

When it comes to cold room panels, durability and moisture resistance are key. These panels need to hold up over time, especially in damp, cold environments where moisture buildup is common. Most cold room panels feature outer skins made from galvanized steel, stainless steel, or aluminum, all of which offer strong protection against rust and corrosion. This means your panels won’t warp, crack, or degrade easily.

The core materials like polyurethane (PU), polyisocyanurate (PIR), or expanded polystyrene (EPS) also play a big role. These cores are resistant to water absorption, helping prevent mold and bacterial growth inside the panels. Mineral wool cores, while excellent for fire resistance, may require special coatings to improve moisture resistance.

Good moisture resistance not only keeps your cold room clean and safe but also extends the life of the panels—saving you money on repairs and replacements in the long run. When shopping for cold room panels, look for materials that guarantee both toughness and protection against moisture for the best performance.

Eco-Friendliness of Cold Room Panel Materials

When choosing cold room panels, eco-friendliness is an important factor for many businesses today. Many panel materials focus on sustainability to reduce environmental impact while maintaining performance.

- Low Environmental Impact Core Materials: Some cores like compressed straw are renewable and biodegradable, offering a greener alternative to traditional foam cores. Polyurethane (PU) and polyisocyanurate (PIR) panels are increasingly made with eco-friendly blowing agents that reduce harmful emissions.

- Recyclable Outer Skins: Steel and aluminum skins are recyclable, which makes cold room panels easier to dispose of responsibly or reuse. Panels with PVC or composite coatings are less eco-friendly but often necessary for specific durability needs.

- Energy Efficiency: Better insulation materials like PIR and PU help reduce energy consumption in cold rooms by maintaining stable temperatures more efficiently. This lowers the cold room’s carbon footprint over time.

- Reduced Waste in Manufacturing: Many manufacturers now optimize panel production to minimize scrap and waste, contributing to sustainability goals.

Choosing eco-friendly cold room panel materials not only benefits the planet but can also improve your business image and lower operating costs through energy savings. For a trusted supplier focused on quality and sustainability, check out Cool Room Master’s range.

Food Storage and Processing

Cold room panels play a huge role in food storage and processing industries across the U.S. They help maintain consistent temperatures necessary to keep food fresh, safe, and compliant with health standards. Whether it’s fruits, vegetables, meat, dairy, or frozen items, these panels ensure products at the right temperature to prevent spoilage.

Thanks to their excellent thermal insulation and moisture resistance, food storage facilities can reduce energy costs while protecting goods from contamination. Plus, many cold room panels come with hygienic surfaces like stainless steel or PVC coatings, which are easy to clean—a must-have in food processing environments.

If you run a business in food production, these panels also support controlled environments for aging, curing, or fermenting foods. Overall, investing in high-quality cold room panel materials directly contributes to better product quality and longer shelf life, making them essential for any modern food storage or processing facility.

Applications of Cold Room Panels Pharmaceutical Storage

Cold room panels play a crucial role in pharmaceutical storage by providing precise temperature control and maintaining product integrity. Medicines, vaccines, and other pharmaceutical products often require strict cool or cold conditions to stay effective. Using cold room panel materials with excellent thermal insulation, like polyurethane cold room panels or PIR insulation panels, helps maintain those necessary temperatures consistently.

These panels also offer strong fire resistance and moisture resistance, which is essential for keeping sensitive drugs safe from environmental damage. When storing pharmaceuticals, contamination and temperature fluctuations must be avoided, and cold room panels are designed to prevent both.

Additionally, materials such as stainless steel cold room panels are often chosen for pharmaceutical cold rooms because they’re easy to clean and resistant to corrosion, ensuring a sterile environment. This makes them ideal for pharmaceutical storage facilities where hygiene standards are very high.

In , choosing the right cold room panels for pharmaceutical storage means:

- Reliable temperature control to preserve sensitive products

- Fire-resistant and moisture-proof materials to protect stored goods

- Hygienic outer skins like stainless steel for clean and safe conditions

This combination ensures pharmaceuticals remain safe from spoilage and damage during storage and transportation.

Applications of Cold Room Panels Industrial and Logistics

Cold room panels play a crucial role in industrial and logistics settings where temperature control is vital. These panels help maintain consistent cold storage for products that need to stay fresh during transportation and warehousing. Whether it’s pharmaceuticals, electronics, or perishable goods, using reliable cold room insulation types like PU or PIR panels ensures energy efficiency and reduces spoilage.

In warehouses and distribution centers, cold room panels create modular, easy-to-expand spaces that adapt to changing storage needs. Their durability, moisture resistance, and fire-resistant properties also protect valuable inventory and equipment. For businesses focused on speed and reliability, panels with galvanized stainless steel or aluminum outer skins provide long-lasting protection against wear and environmental exposure.

In short, cold room panels are essential for industrial and logistics operations aiming to keep products safe, maintain quality, and optimize energy use through efficient cold storage solutions.

Applications of Cold Room Panels Commercial Use

Cold room panels are a popular choice for commercial spaces that need reliable temperature control. They’re widely used in grocery stores, supermarkets, restaurants, and convenience stores to keep produce, dairy, meat, and beverages fresh. These panels help maintain consistent cold temperatures while saving energy and reducing spoilage.

Retailers also rely on cold room panels for walk-in coolers and freezers, making them ideal for any business dealing with perishable goods. They’re easy to install and offer good durability, which is perfect for busy commercial environments where efficiency and hygiene are must-haves.

If you’re considering panels for a commercial setup, check out polyurethane cold room panels and EPS cold storage panels for options known for energy efficiency and strong insulation. These panels help commercial businesses cut costs on energy bills while keeping products in top condition.

In short, cold room panels provide a practical, cost-effective solution for storing perishable goods in any commercial setting.

How to Choose the Right Cold Room Panel Material

Picking the right cold room panel material depends on what you need for your space. Here’s what to keep in mind:

- Thermal insulation: Look for materials with strong insulation like polyurethane (PU) or polyisocyanurate (PIR). Good insulation cuts energy costs and keeps your stored items fresh.

- Fire resistance: If safety is key, choose fire-resistant options like mineral wool panels.

- Durability and moisture resistance: In humid or wet environments, panels with galvanized steel, stainless steel, or PVC coatings work best to avoid rust and damage.

- Budget: Polyurethane panels are popular for being cost-effective with excellent insulation. Expanded polystyrene (EPS) is a cheaper option but may not last as long.

- Eco-friendliness: If you want green options, compressed straw or mineral wool panels are environmentally friendly choices.

- Application needs: Different industries have different requirements. Food storage might need food-safe, easy-to-clean outer skins, while pharmaceuticals need tight insulation and controlled environments.

By focusing on these factors, you can choose panels that fit your budget and performance needs, ensuring your cold room operates efficiently in your local U.S. climate.

Installation Best Practices

Installing cold room panels the right way is key to getting the best performance and longevity from your cold room. Here are some essential tips to keep in mind:

- Prepare a Level Surface: Ensure the floor or foundation is flat and stable before starting. Uneven surfaces can cause gaps or panel misalignment.

- Follow Manufacturer Guidelines: Always stick to the installation steps provided by the panel manufacturer to maintain warranty and performance.

- Use Proper Sealing: Apply seals and gaskets as recommended to prevent cold air leaks and moisture ingress.

- Secure Panels Firmly: Panels should be fastened tightly using the right screws or cam locks to maintain structural integrity.

- Plan Panel Layout: Lay out panels to minimize cuts and joints, which helps improve insulation and speed up assembly.

- Handle Panels Carefully: Avoid dropping or bending panels to prevent damage to core insulation or outer skins.

- Install Electrical Components Safely: If wiring runs through panels, follow best practices for cutting and fitting to avoid compromising insulation. (See how to run wires through EPS panels safely)

- Check for Proper Alignment: Ensure all panel joints line up evenly for airtight seals and uniform appearance.

A careful installation sets the foundation for efficient thermal insulation, fire resistance, and durability—basically everything you need your cold room to do well. If you’re unsure about handling installation yourself, professional installers can save time and avoid costly mistakes.

Maintenance for Longevity

Keeping your cold room panels in good shape ensures they last longer and perform well. Here are some simple maintenance tips to extend the life of your cold room panels:

- Regular Cleaning Use mild soap and water to clean the panel surfaces. Avoid harsh chemicals or abrasive tools that can damage the outer skin, especially if it’s steel or aluminum.

- Check for Moisture and Leaks Inspect joints and seals regularly to stop moisture buildup. Any leaks or condensation can degrade insulation materials like polyurethane or PIR panels over time.

- Inspect for Physical Damage Look for dents, scratches, or corrosion on the panel skins. Damaged panels can reduce thermal efficiency, so fix minor issues early.

- Maintain Door Seals and Hardware Cold room doors need well-maintained seals and hinges to prevent air leaks. Replace worn gaskets to keep insulation tight and energy costs down.

- Control Pest Access Ensure that pests can’t get inside as they might damage insulation cores, especially natural ones like compressed straw.

- Schedule Professional Inspections Having experts check panel integrity and insulation performance yearly helps catch hidden problems.

By following these simple steps, you’ll keep your cold room panels reliable, energy-efficient, and durable for years to come.

Why Choose Cool Room Master for Your Cold Room Panels

When it comes to cold room panels, Cool Room Master stands out with honest pricing, real quality, and better service. We know choosing the right panels for your cold storage needs in the U.S. market is important, so we focus on delivering products that offer top thermal insulation, durability, and energy efficiency without breaking your budget.

Here’s why working with Cool Room Master makes sense:

- Honest Pricing – No hidden fees or surprises. We provide clear quotes so you know exactly what you’re paying for.

- Real Quality – Our panels come with premium core materials like polyurethane PU and PIR, combined with durable outer skins such as galvanized steel or aluminum. This means reliable performance that lasts.

- Better Service – From helping you pick the right panel type to quick delivery and expert installation advice, we support you every step of the way.

- Custom Solutions – Whether you need panels for food storage, pharmaceuticals, or industrial use, we tailor solutions to fit your exact needs.

- Local Expertise – We understand the climate and regulations in the United States, ensuring your cold rooms meet all standards for safety and efficiency.

- Energy Efficient Options – Our panels help reduce your energy costs with high insulation values designed specifically for U.S. cold room applications.

Choose Cool Room Master for trusted cold room panels that combine performance and value. Reach out today and get the best materials and support for your cold storage project.